When it comes to creating stuff with machines, the form of the thread of the screw inside the extrusion extruder is the BOMB. SEVENSTARS MACHINERY knows this well! The screw’s design can play a huge role in how smoothly a machine is able to churn out products. If the screw isn’t designed correctly, that can slow up production, consume more energy and even affect the quality of what was being made. So let’s get into more and more as to why extrusion extruder screw geometry is such a big deal when it comes to production efficiency

Know how your extrusion extruder screws can affect your production efficiency

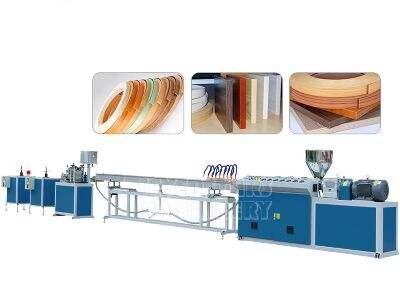

The screw in an extrusion extruder can be compared with the heart of the machine. It shoves its content through the machine to make what we want. If the screw — its twists, turns, its very shape — isn’t a good match for what the machine is trying to make, the machine can labor harder and longer. SEVENSTARS MACHINERY always follow the concept of screw design, depending on the job to design the screw, to ensure that the machine can get the best normal use

Discover why choosing the correct extruder screw design is essential for high output

Speed isn’t the only thing to consider when opting for the right screw design. It’s also useful in making more of whatever the machine is producing. That means the machine will be able to produce more products at a faster rate, and faster production always means more business

Investigate effect of screw geometry on the quality of the product

The design and features of the extruder screw not only determine how much stuff you can make but also the quality of the finished product in both appearance and functionality. If the screw isn’t right, the products can end up looking bad or may break too easily. Inspiration of design SEVENSTARS MACHINERY screw is designed for producing products in high quality according to specific demands

Learn how various types of screw designs can impact energy use and maintenance

A wrong screw in the wrong place can force the machine to suck more power and wear itself out earlier. That means, more electricity bills and more costs when you really have to get the machine fixed. We manufacture our screws to keep energy use low, your machines running well, your products precise and your pocketbook full

Select the right extruder screw geometry for maximum efficiency in your production

Choose the Right Extrusion Screw Design You can make a huge difference in your production process by choosing the right type of screw in the extrusion extruder. SEVENSTARS MACHINERY can help select the optimum geometry that will best suit your needs and keep production running smoothly and efficiently. This decision can have an extreme impact on how well your business does – it can help you do better (and faster) and save money

Table of Contents

- Know how your extrusion extruder screws can affect your production efficiency

- Discover why choosing the correct extruder screw design is essential for high output

- Investigate effect of screw geometry on the quality of the product

- Learn how various types of screw designs can impact energy use and maintenance

- Select the right extruder screw geometry for maximum efficiency in your production