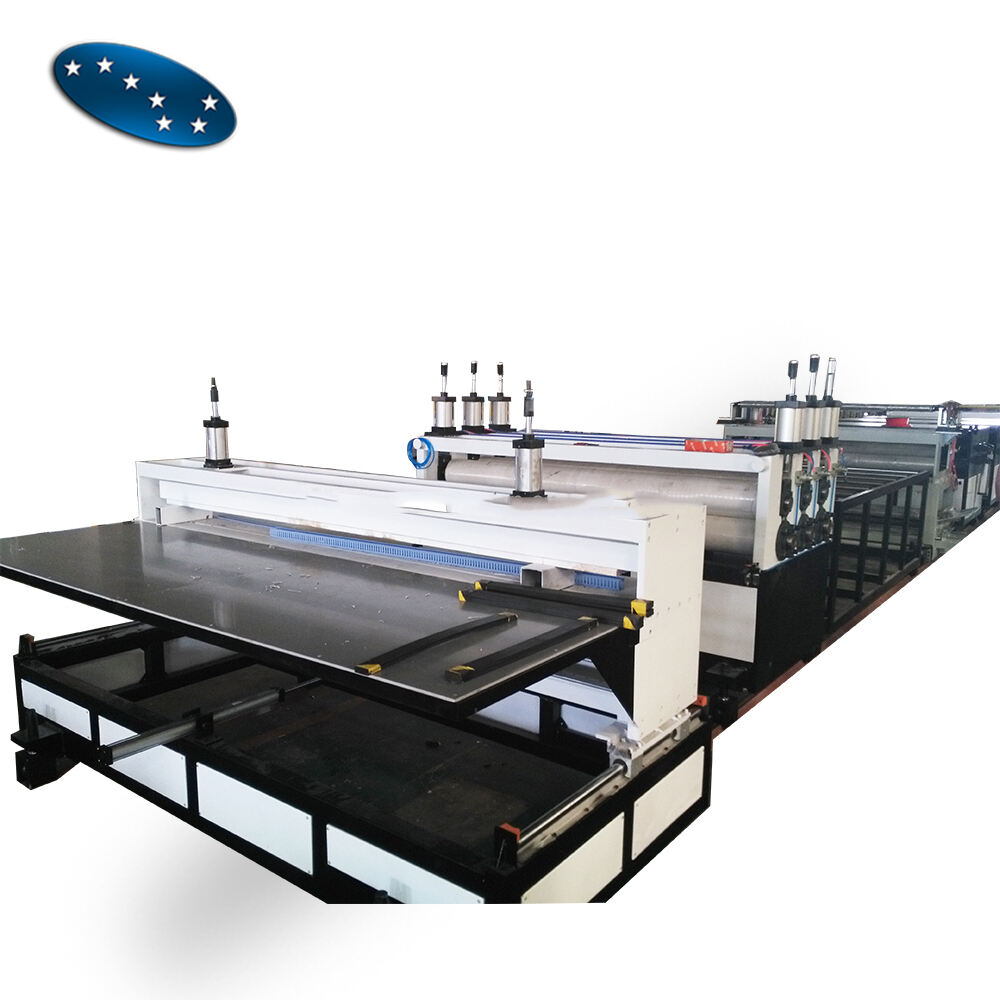

A lot has been altered in the extrusion absorbing system due to new requirements and ideas in technology. Rather these systems are used for forming materials (plastics or metals, for example) by forcing the materials through a shaped opening in a die. Both SEVENSTARS MACHINERY and companies like it are constantly improving these systems. They’re dying to make them faster, more reliable and easier to use. We’re going to explore what’s really causing these shifts and how new technology is really shaking things up in the world of extrusion extruders.

They are the prime motive power for the modern extruders in extrusion systems

The primary driver of the growth of modern extrusion systems comes from needing to producing faster and more cost effectively. The bigger an industry grows, the bigger its machines need to be to meet high demand. SEVENSTARS MACHINERY concentrate on making machines which are not only more faster but also more environmental protection more energy saving. That makes it less expensive and better for the planet for companies.

Greater efficiency and product quality with advanced extrusion technology

New technologies that are making extrusion machines better. These enhancements include improved controls, more durable materials to build the machines from and new designs that generate better products. SEVENSTARS uses these technologies to ensure their extrusion extruder do what you need them to- and to make products that look great and function perfectly.

Leading the way in environmentally-friendly extrusion solutions

In the present days, this planet needs to be cared. SEVENSTARS MACHINERY is developing extruder that require less energy and materials. They also are trying to make machines that can use recycled materials. This is good, as it cuts down on waste and pollution.

Adapting extruder systems to the many requirements in today´s industries

Extruders Get Noisy, Cost to Quiet Them 1. SEVENSTARS MACHINERY designs machines that change over to what each sector desires. Whether you’re making simple forms or intricate patterns, their machines are designed to be versatile and able to tackle any type of job.

Leveraging automation and digitalization

Automation and digital tools are a huge part of contemporary extruder machine. These instruments ensure that the machines are doing their job right and can even regulate small issues independently. SEVENSTARS MACHINERY adopts these high-technology equipment to make the machines better quality and more competitive. This allows businesses to keep on churning, with fewer stop-starts in production.

Conclusion

extrusion extruder technology is always improving, it’s driven by new needs and better technology and a drive to be greener. Companies such as SEVENSTARS MACHINERY are at the forefront of this change, and are ensuring that their machines are state-of-the-art and prepared for the future.

Table of Contents

- They are the prime motive power for the modern extruders in extrusion systems

- Greater efficiency and product quality with advanced extrusion technology

- Leading the way in environmentally-friendly extrusion solutions

- Adapting extruder systems to the many requirements in today´s industries

- Leveraging automation and digitalization

- Conclusion