The Calibration of The PVC Extrusion Machine

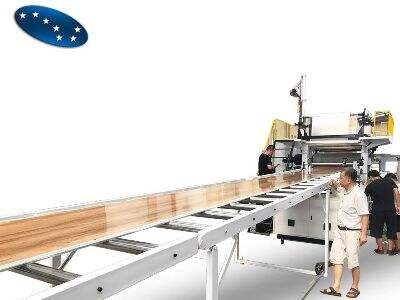

One of the key processes to producing high-quality PVC products. Calibration is when you nail the machine so that it makes the products exactly like they are supposed to. We understand how important this is at SEVENSTARS MACHINERY. By calibrating our machines properly, it reduces the opportunity for failure when our products are put to the test and this means our PVC products are as strong, durable and aesthetically pleasing as possible.

The significance of calibration in PVC extrusion machine in producing high quality products

Calibrating a PVC extrusion machine is* like” tuning” a guitar before a concert. You have to do it right or the music won’t sound good. On a similar note, the PVC products won’t come out right if the pet extrusion machine isn’t properly set. They could be a tad too thin or too thick or unevenly surfaced. Here at SEVENSTARS MACHINERY, we intend to get everything done perfectly, as we adjusted all machinery good for PVC products.

Key advantages that your PVC extrusion process can benefit from with accurate calibration

Optimized calibration of your extrusion feeders also results in improved final product quality. So they can take more pressure, last longer and fit perfectly where they are meant to. This step assists us at SEVENSTARS MACHINERY ensure our customers are purchasing their perfect machine that will not disappoint.

Maintaining consistent product quality through calibration of PVC extruder machines

One major benefit of accurate calibration is to maintain the product quality. That is, that every single item it makes is equally as good as the one before it. It matters to us, because it shows we care about every product we put out of our machines. We know that the quality is the soul of the machine, so we had put a lot of investment to weave.

Boosting product life and strength while maintaining an accurate machine calibration in PVC extrusion

Strong machine starts with the strong machine to make strong and durable PVC product. These items can withstand wear and tear, such are perfect for a lot of use. We at SEVENSTARS MACHINERY do technicians provide the best calibration procedures to our single screw extrusion machine to make the life longer of the machines, having strength throughout the work life of our machines.

The influence of calibration in the optimization of PVC extrusion with respect to best possible product quality

Calibration isn’t only responsible for producing good products, it also makes the entire profile extrusion process better. When the polymer extrusion machine is set up right, we can work more quickly and waste less material.” This not only saves us SEVENSTARS MACHINERY money, but also enables our factory to be environmentally friendly. And it maintains the quality of the end product at the highest level.

(SEVENSTARS MACHINERY) Concentration and precise: Make sure every component exquisite.: The best equipment determines an excellent product. That’s how we make sure our machines are in peak condition, meaning they’ll perform better and last longer in every piece of gear we make.

Table of Contents

- The Calibration of The PVC Extrusion Machine

- The significance of calibration in PVC extrusion machine in producing high quality products

- Key advantages that your PVC extrusion process can benefit from with accurate calibration

- Maintaining consistent product quality through calibration of PVC extruder machines

- Boosting product life and strength while maintaining an accurate machine calibration in PVC extrusion

- The influence of calibration in the optimization of PVC extrusion with respect to best possible product quality