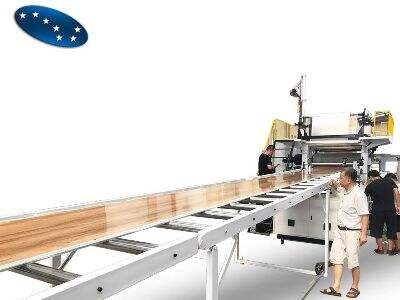

Machines are very, very crucial when it comes to producing PVC products. One important part of these machines is their cooling systems. SEVENSTARS MACHINERY understands that when you don’t have a good cooling system, everything can go downhill very quickly. So what makes these cooling systems so vital? Let's break it down

Keep ideal temperature to ensure bit of pvc extrusion consistent output ratio

The cooling systems of (PVC extrusion machines) are akin to the air conditioning of your home on a hot summer day. When it gets too hot, things melt or things get screwed up. SEVENSTARS MACHINERY uses cooling fans to ensure it's the right temperature so that you get perfect PVC every time. Die temps that are not hot enough or too cold will not properly form the PVC and none of us want that

Stop PVC profiles from over heating and warping during extrusion

Pretend you’re baking cookies and they get left in the oven too long. What happens? They burn and warp, right? It's sort of like PVC when it's being created. The P.V.C. does not get scorching, thanks to the cooling systems. If PVC gets too hot, it can warp or twist, so it may no longer fit where it’s intended to go. That would be terrible, especially when making something significant like window frames or pipes

PVC Extrusion Machine Cooling System Insures Product Quality and Durability

A good cooling system isn’t only for preventing overheating, but to ensure the PVC products are tough and have a long shelf life. You’ll often achieve this by melting PVC; like other materials, once PVC cools back down, it’ll be in the shape it was supposed to take and will be strong enough to do the job it’s supposed to do. SEVENSTARS MACHINERY concentrates on this to make sure the entire PVC items are of the best quality

Do more with less by utilizing quality cooling products

For the machines to operate faster and keep from breaking, they need cooling systems. Without them the machines would have to stop a ton to cool down or if something fucked up the temps. That would slow everything down, be difficult to get orders out on schedule. SEVENSTARS MACHINERY uses cooling systems to ensure everything runs to perfection and no time is wasted

Need for good Cooling system to maximize production and to minimize wastage

And last but not least, decent cooling system to make the best use of the materials and time. They are part of what ensures that there is limited waste, because everything is done right the first time. This is better for the planet, and saves money as well. And that means SEVENSTARS MACHINERY can produce more PVC products faster to satisfy their customers

So, PVC extrusion machines need to be super reliable in their cooling systems. They maintain the machine well, ensure the quality of the PVC products and assist in doing everything in time while maintaining effectiveness without wasting materials. And that is why the SEVENSTARS MACHINERY takes them seriously

Table of Contents

- Keep ideal temperature to ensure bit of pvc extrusion consistent output ratio

- Stop PVC profiles from over heating and warping during extrusion

- PVC Extrusion Machine Cooling System Insures Product Quality and Durability

- Do more with less by utilizing quality cooling products

- Need for good Cooling system to maximize production and to minimize wastage