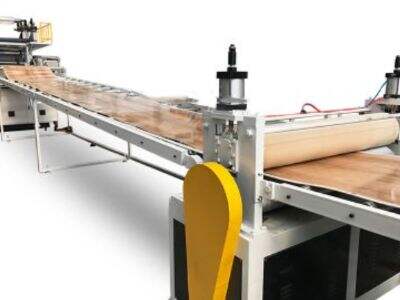

The auto loading feeder vacuum technology from SEVENSTARS MACHINERY is changing the way power conveying materials in various industries. This system is based on pneumatic transportation in a strong vacuum, which allows the materials to be carried without detriment, in a clean and no contaminating way. This procedure saves time and aids in maintaining a clean and safe work environment. Now, I’d like to get a bit more in-depth about ways in which this technology is helpful for clean material transfer.

Advantages of Auto-Load Feeder Suction Conveying the Clean Solution for Material Transfer

An auto-loader feeder with vacuum designed by SEVENSTARS MACHINERY has several features and advantages for transferring clean materials. This is because, as the material is transported within a closed system, there is little exposure to the outside. This substantially reduces how often one's waiting area is contaminated with dust or other particulates. The device secures in which no materials are spilled during transfer, maintaining a clean and waste-free work area.

How Contamination During Material Transfer Is Minimized by Vacuum Technology

The automatic plate cutting machine of the documents in the feeder is based on vacuum technology which ensures, that documents can’t be damaged in any way. This avoids the possibility of any contaminated product entering the material transferred. Additionally, the system is gentle with materials, reducing the generation of smaller, dust-like particles which can contaminate the work area.

Precision and High-Speed Material Transfer with Auto -Loading Feeder Vacuum Technology

SEVENSTARS MACHINERY's vacuum system is not only clean, but also accuracy and efficiency. The process can be adjusted to master perfectly the different materials to be treated and to transport it at the ideal speed. This accuracy ensures that just the right amount of material gets transferred with no waste or shortage of material – a critical factor in industries that require accuracy.

How Auto-Loading Feeder Vacuum Technology Avoids Material Spillage and Contamination

Its non-spill technology is just another feature that set them apart from the rest. The contents aren’t released until they have arrived and the materials stay within the vacuum system at all times. This technique is a lot cleaner than conventional transfer methods, which may lead to the problems of material spillage and contamination.

Industrial Vacuum Auto Loading Feeder for Material Transfer Now Makes Workplace Safer and Cleaner

The auto loader vacuum technology in material transfer applications adds significantly to fewer dusting on the job site. The technology, by limiting human contact with the substances, also lessens the potential for mishaps and harm to the health of those exposed to the materials. Moreover, the clean transfer method also results in the work place stays clean, with the absence of material residue that can produce slippery, or other, hazards.

Table of Contents

- Advantages of Auto-Load Feeder Suction Conveying the Clean Solution for Material Transfer

- How Contamination During Material Transfer Is Minimized by Vacuum Technology

- Precision and High-Speed Material Transfer with Auto -Loading Feeder Vacuum Technology

- How Auto-Loading Feeder Vacuum Technology Avoids Material Spillage and Contamination

- Industrial Vacuum Auto Loading Feeder for Material Transfer Now Makes Workplace Safer and Cleaner