Loading Feeder for Big Production Companies

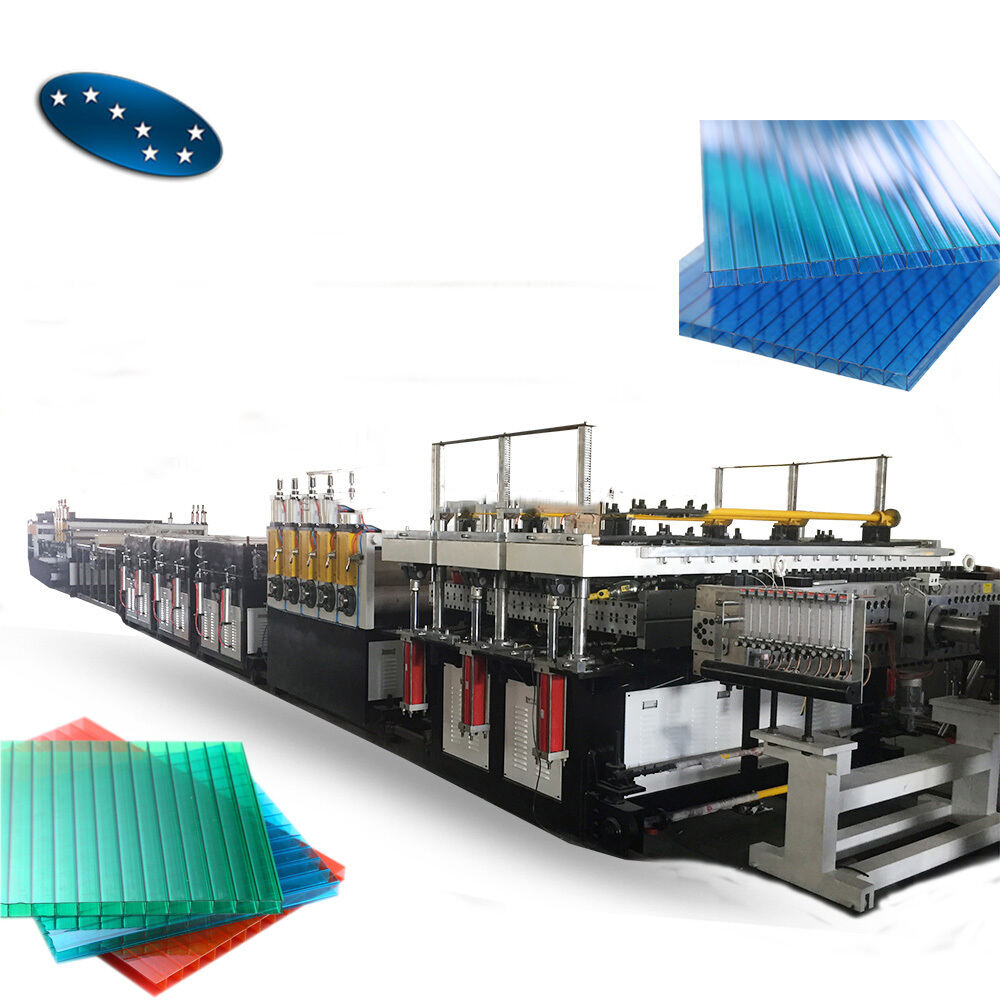

When you’re running a big factory, you want machines that save time and money by working well. One of these machines is Centralized auto loader feeder manufactured by SEVENSTARS MACHINERY. The other camp, big factories, would find this extruder machine for plastic to be the one for them because it does most of the dirty work on autopilot which means things will run smoother and it will require less manual input or the occasional distraction. And let’s discuss why big factories love this machine.

Advantages of Loading Feeder Machine

The ability to have all the stations combined in one centralized auto loading feeder is optimal to achieve continuous production and increased overall efficiency in a large factory. Picture all the factory’s materials zipping along and arriving perfectly timed, with no mix-ups. That’s the function of a central auto loading feeder. It’s as if there were a super-smart assistant at a factory who knows exactly when and where to supply the materials. That means everything runs faster and smoother, and that factories are able to produce more products in less time.

Human labor can be reduced and material loss can also be limited by using centralized auto loading feeder in big factory to cut down the cost of production.

Factories pay a lot of people to move materials and deal with waste. But a centralized auto loading feeder requires fewer people to do these jobs, and less material gets wasted. That way, factories can save some money, which they can use to do other important stuff, like making better products or paying workers more.

Thanks to the automatic feeding structure, the chances of industrial accidents can be minimized and the centralized SEVENSTARS MACHINERY extruder machine is suitable for use in huge factories. Factories can be dangerous with lots of heavy materials, and machines. Now and then, crashes occur when people become fatigued or make errors. But when machines such as the centralized auto loading feeder take over this task, robots are there to move the pieces, and they never get tired or make mistakes. The factory is therefore a lot safer to work in.

Consistent accuracy of feeding from a centralized auto loading feeder allows high-quality output in large factory system.

It’s incredibly import for factories to produce products of the exact same high quality. This can be difficult when other people are doing all the work, because people work a little differently from each other. But for a machine such as the centralized auto loading feeder, whose work is identical every time, one product is as good as the previous one.

Since large plants are growing, and to meet future growth a centralized auto loader feeding system readily adapts to higher production of a centralized auto loading hopper. Factories just want to make more and be bigger. The centralized auto loading feeder is an ideal solution for this, as SEVENSTARS MACHINERY PP Hollow sheet machine can take on increased amount of jobs as the factory grows. It’s as if we have a team member that scales with the company, is trained on everything the company has done in the past and can tackle anything that comes next. It also gives factories an easier time planning ahead and expanding.

Table of Contents

- Loading Feeder for Big Production Companies

- Advantages of Loading Feeder Machine

- Human labor can be reduced and material loss can also be limited by using centralized auto loading feeder in big factory to cut down the cost of production.

- Consistent accuracy of feeding from a centralized auto loading feeder allows high-quality output in large factory system.