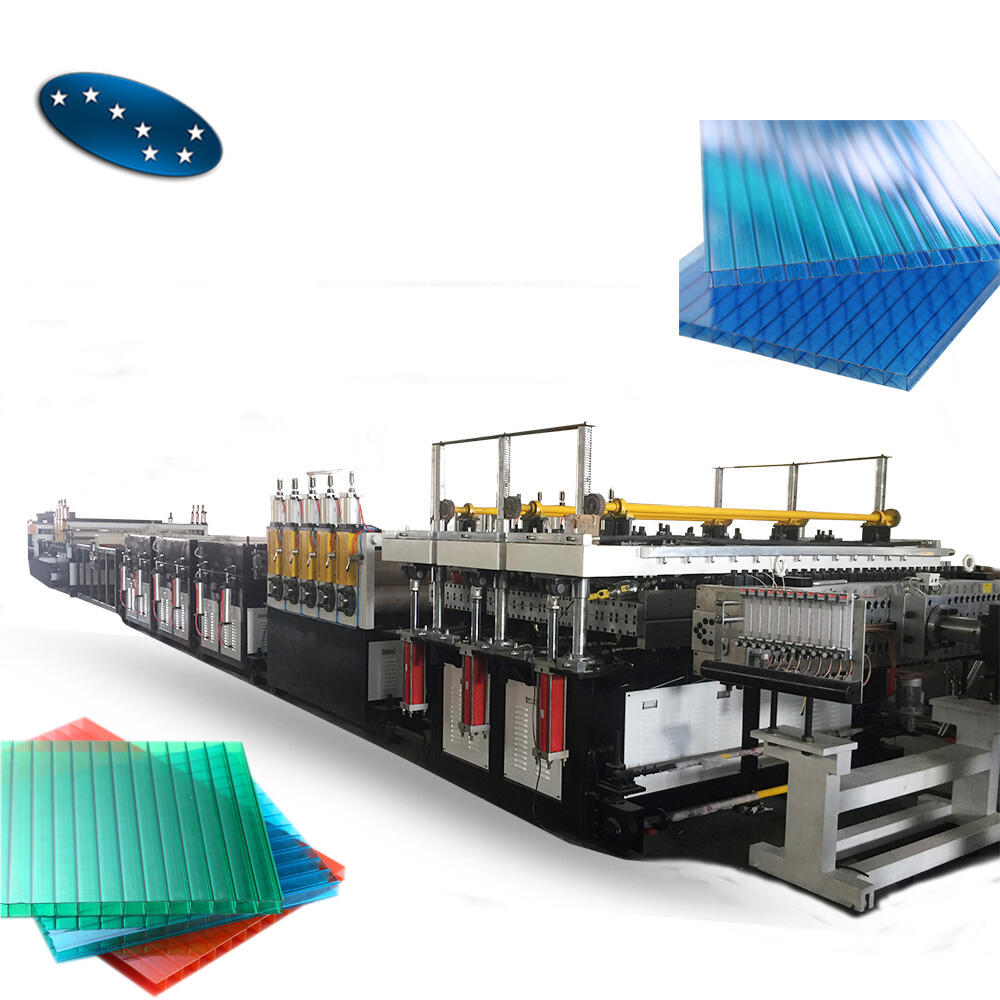

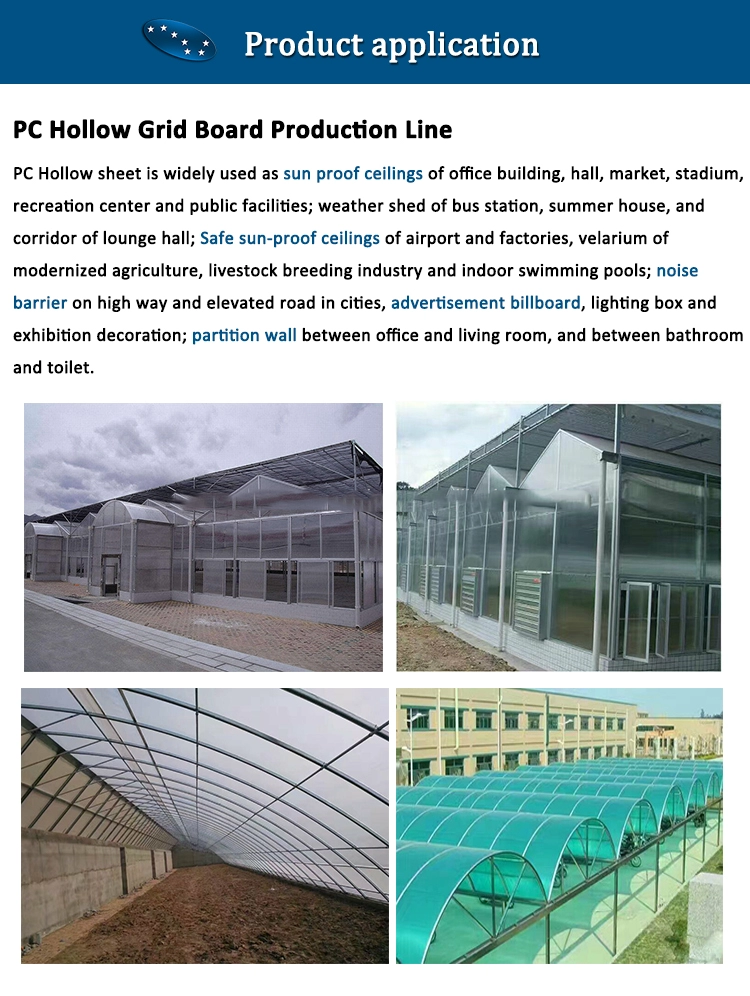

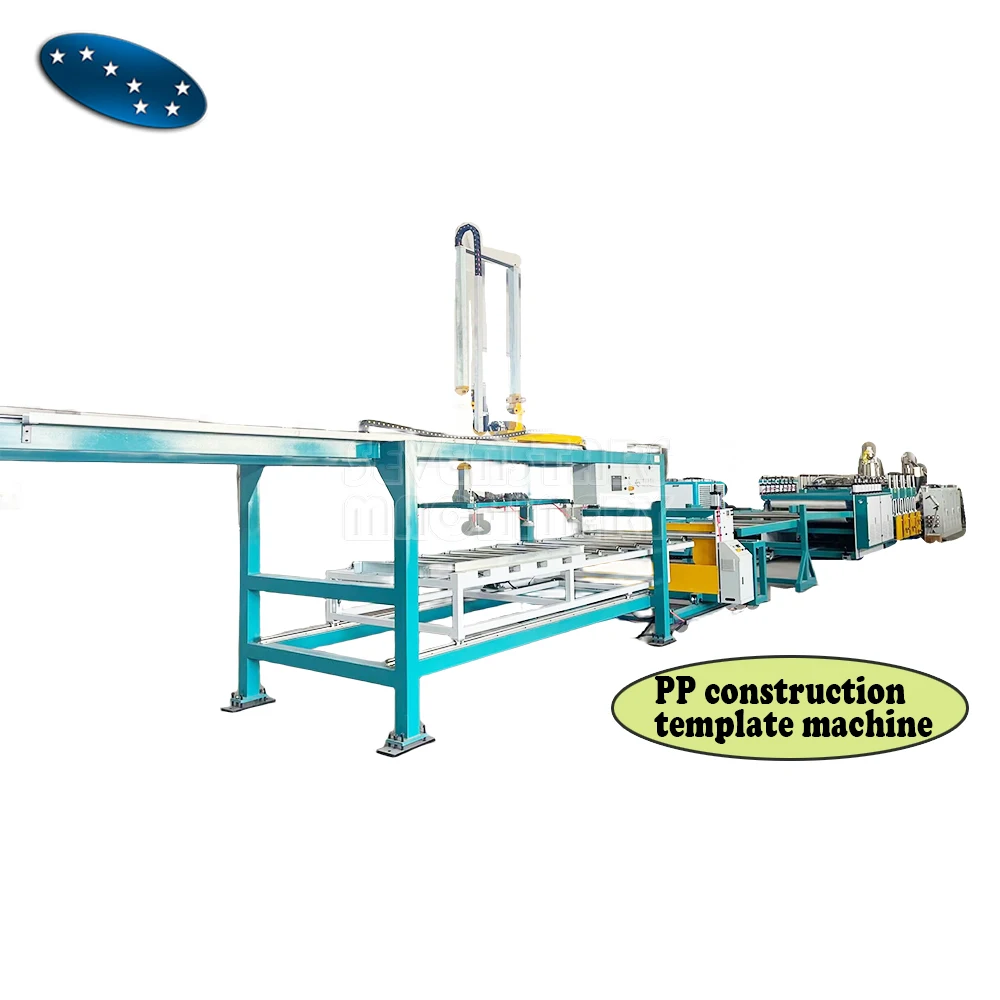

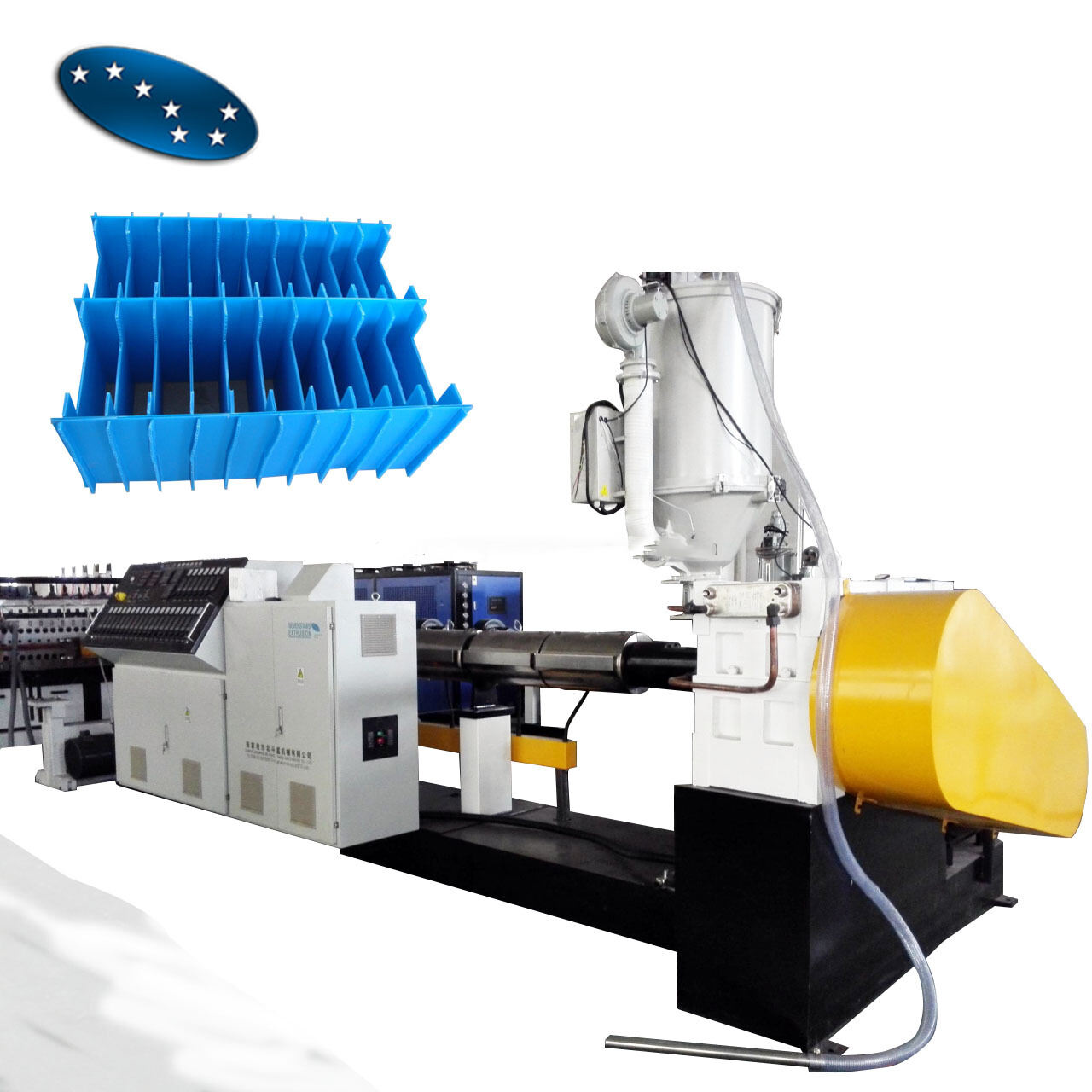

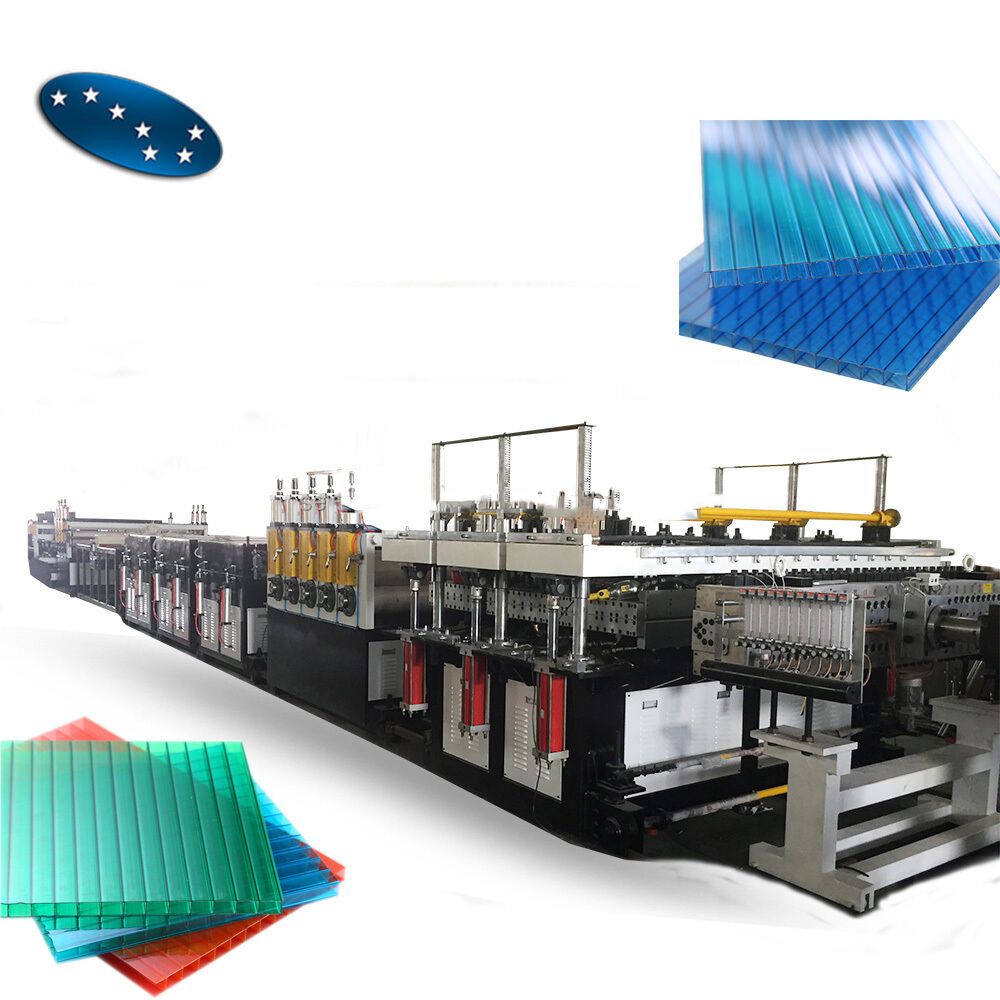

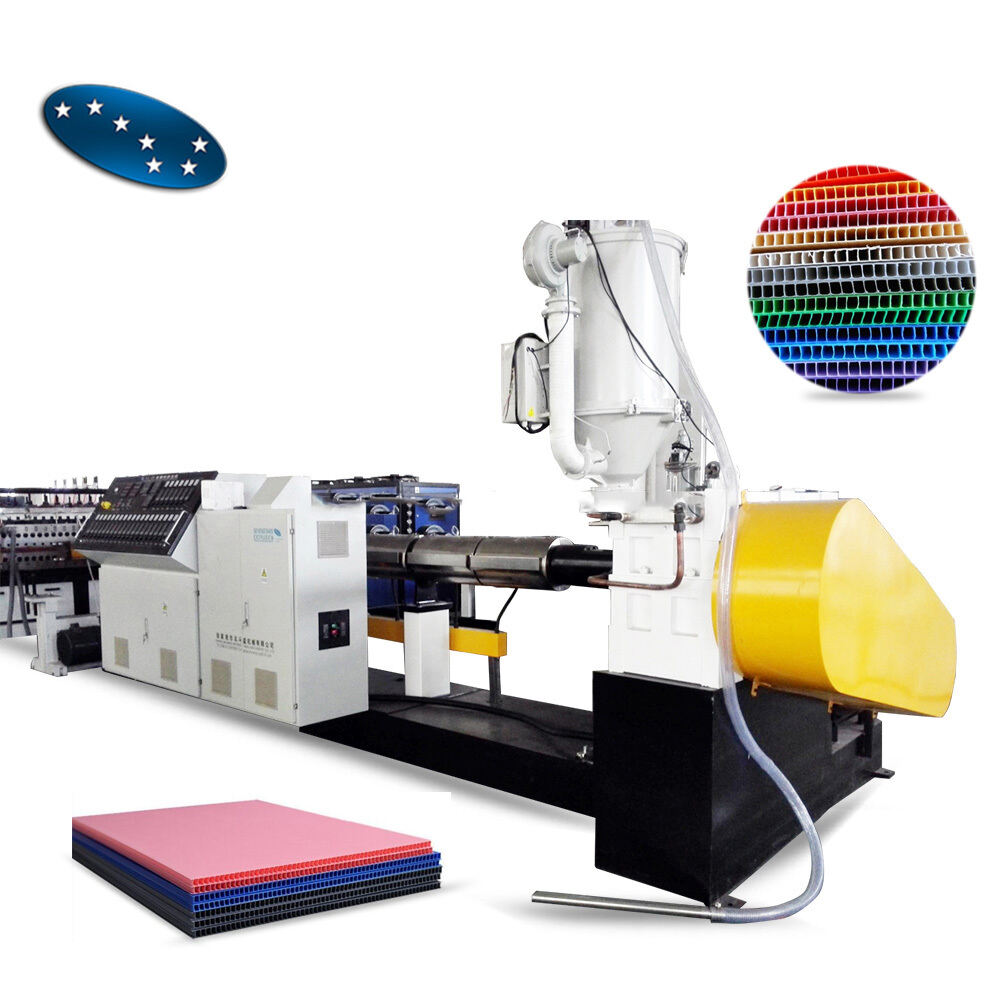

Výrobní linka prázdných listů PC/PE/PP je určena k výrobě prázdných profilových desek z materiálů PC, PP, PE. Produkty jsou široce používány v budování, dekoraci, reklamním rozložení, izolaci silničního hluku, střešních konstrukcích a balení. Prázdná deska z PP může nahradit kartón díky vlastnostem jako lehkost, vysoká pevnost, odolnost proti vlhku a proti bakteriím. Podrobný popis jednotlivých částí strojové linky pro výrobu prázdných listů PC/PE/PP.

1. Vakuový kalibr je vybaven odolností proti přetírání, je bez znečištění a zdvýkání, spuštění a úroveňování formovaných desek je mnohem snadnější kontrolovat.

2. Vysokorychlostní šroub, nízká spotřeba energie s vysokou otáčivou rychlostí pro ladění s čerpadlem a stabilním tlakem; výkonnost je o 25 % vyšší než u extručních linií jiných značek díky speciálnímu návrhu formovacích desek.

3. Speciálně navržený chladič pro všechny části formovacích desek a jedinečně navržený vakuumový systém pro každou část formovací desky.

4. Speciálně navržená teplotní kontrola trouby s křížovým tepelným sbalením, která je mnohem snadnější k ovládání než extruční linky jiných značek.

5. Tvrdost tahacích valů lze přizpůsobit podle požadavků, aby se jejich roztažení prodloužilo.

6. Kapacita vzduchu prázdného listu a nízkého tlaku lze mírně upravit a ovládat, což je snazší než u jakékoli jiné značky extručních linií.

7. Unikátní T-Die vyrobená společností JC Times je speciálně navržena pro duté listy z PP. Hustota dutého listu může být od 2 mm do 10 mm s dvojitou stěnou. Řebra mezi stěnami mohou mít obdélníkový a šikmý tvar.

8. Proti-UV koeextruovaná vrstva může být jednostranná nebo dvoustranná, vnější povrchy mohou být pískovité nebo lesklé podle konfiguračních požadavků. Do původních materiálů lze namíchat vysoké procento recyklovaných flak.

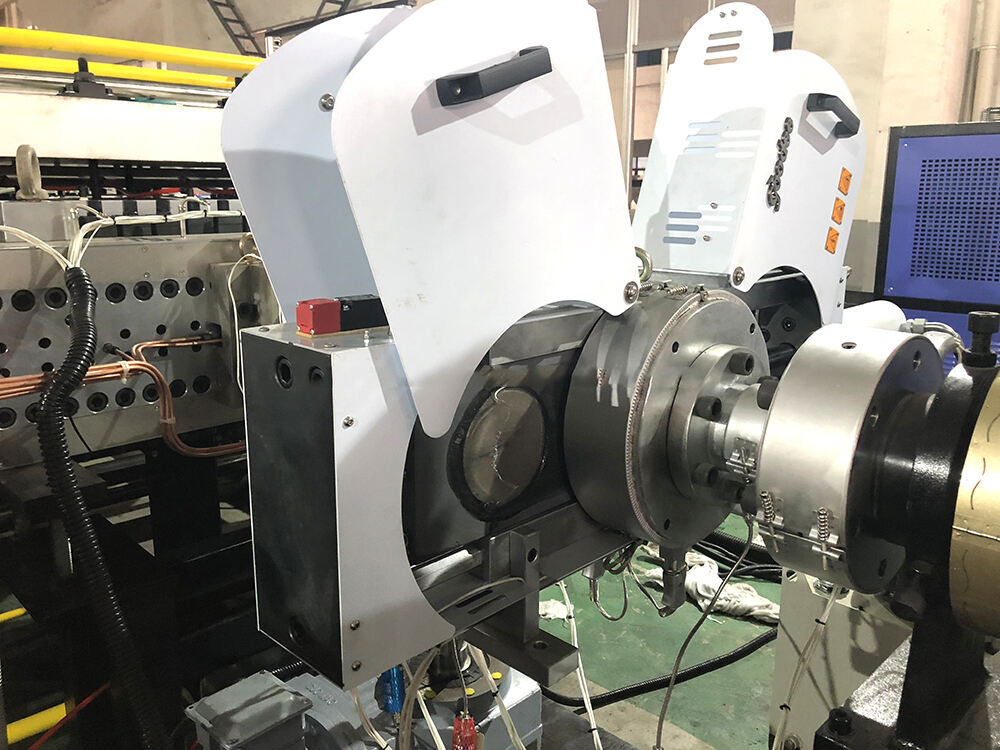

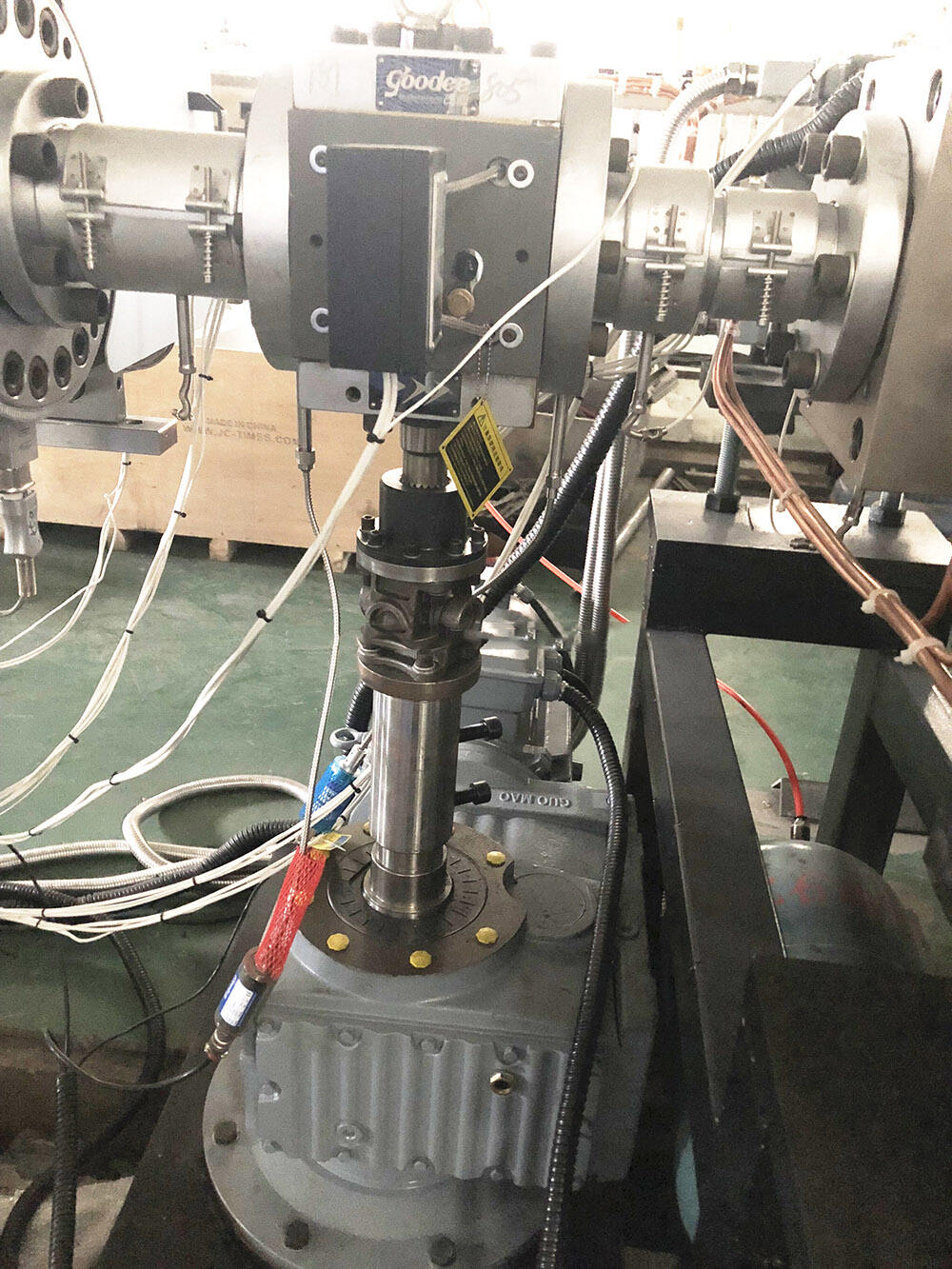

Měnič filtru pro recyklační materiál

Měnič filtru pro recyklační materiál

Mold na vysokorychlostní extruzi

Mold na vysokorychlostní extruzi

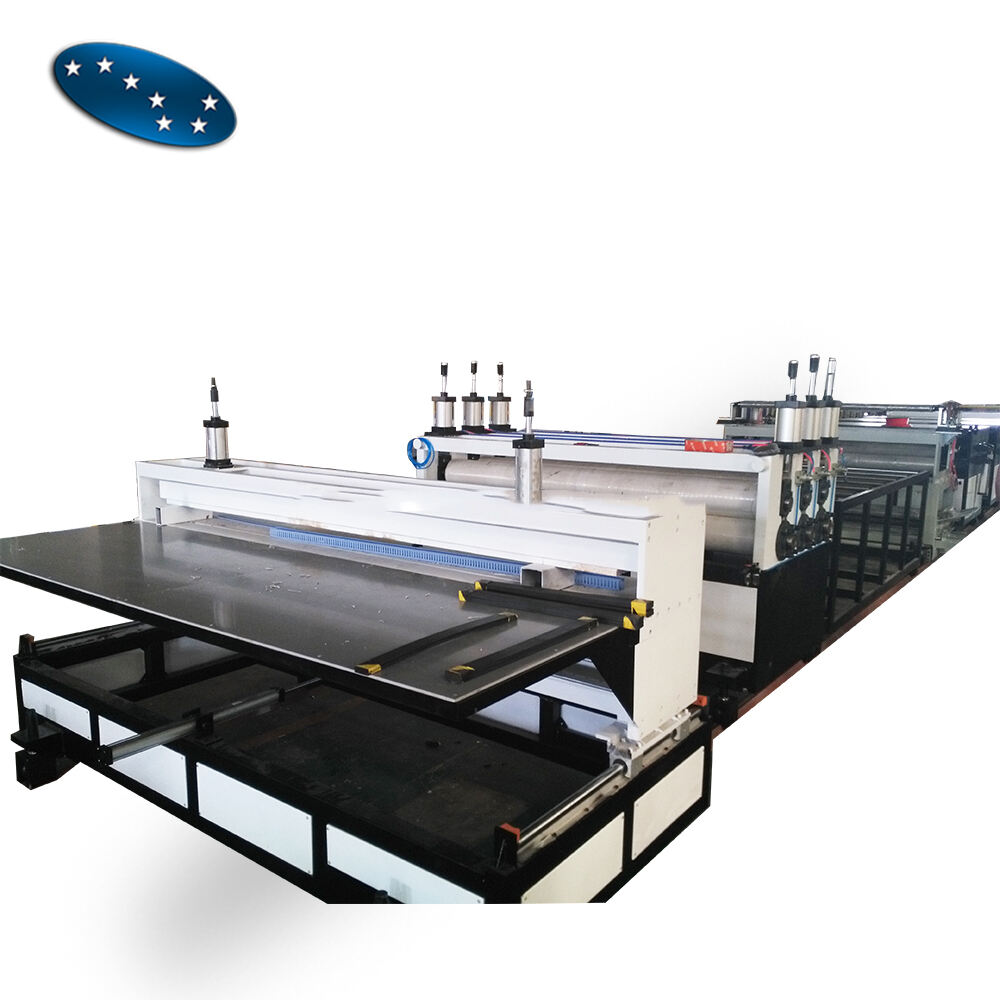

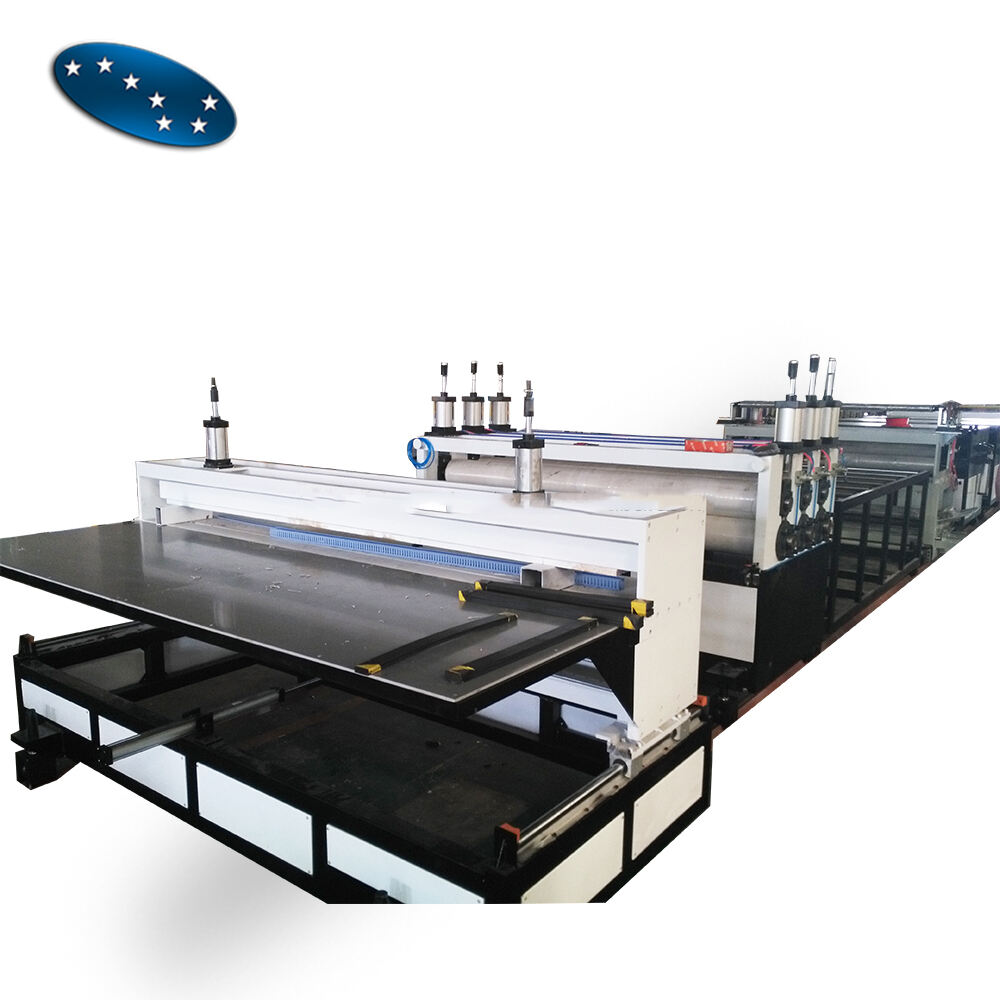

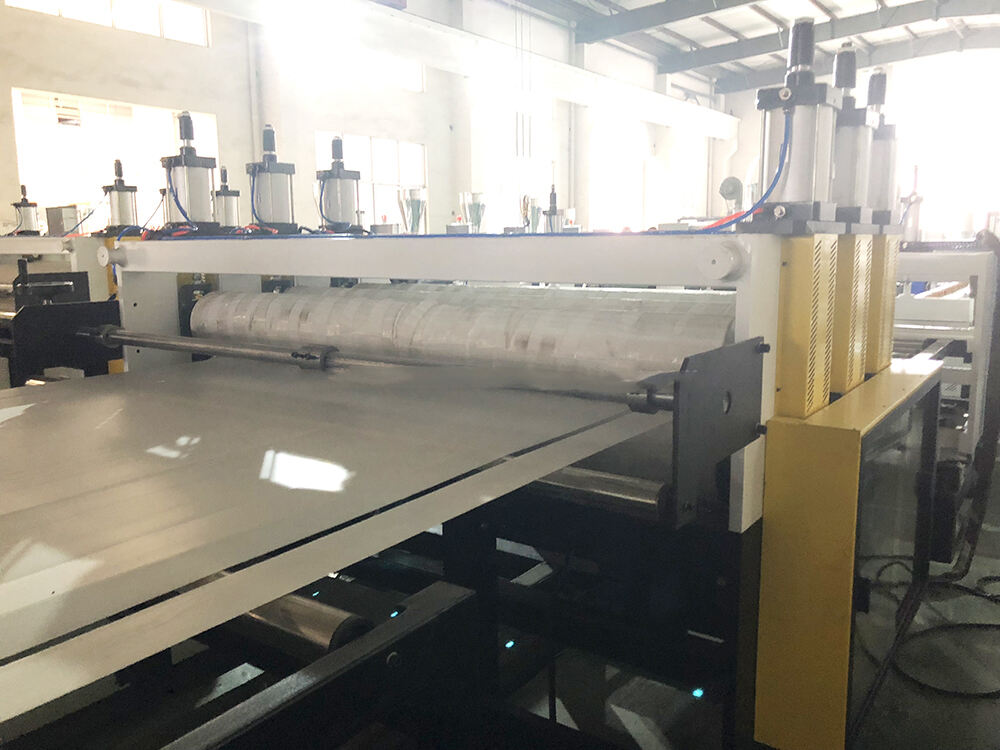

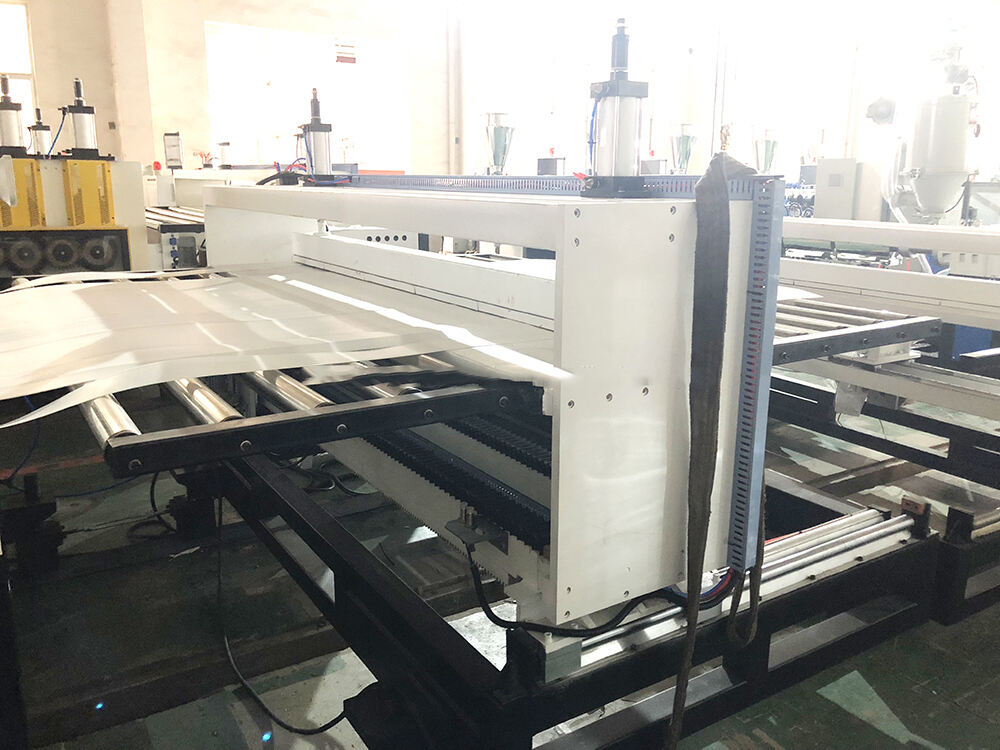

První tahací stroj

První tahací stroj

Druhý tahací stroj

Druhý tahací stroj

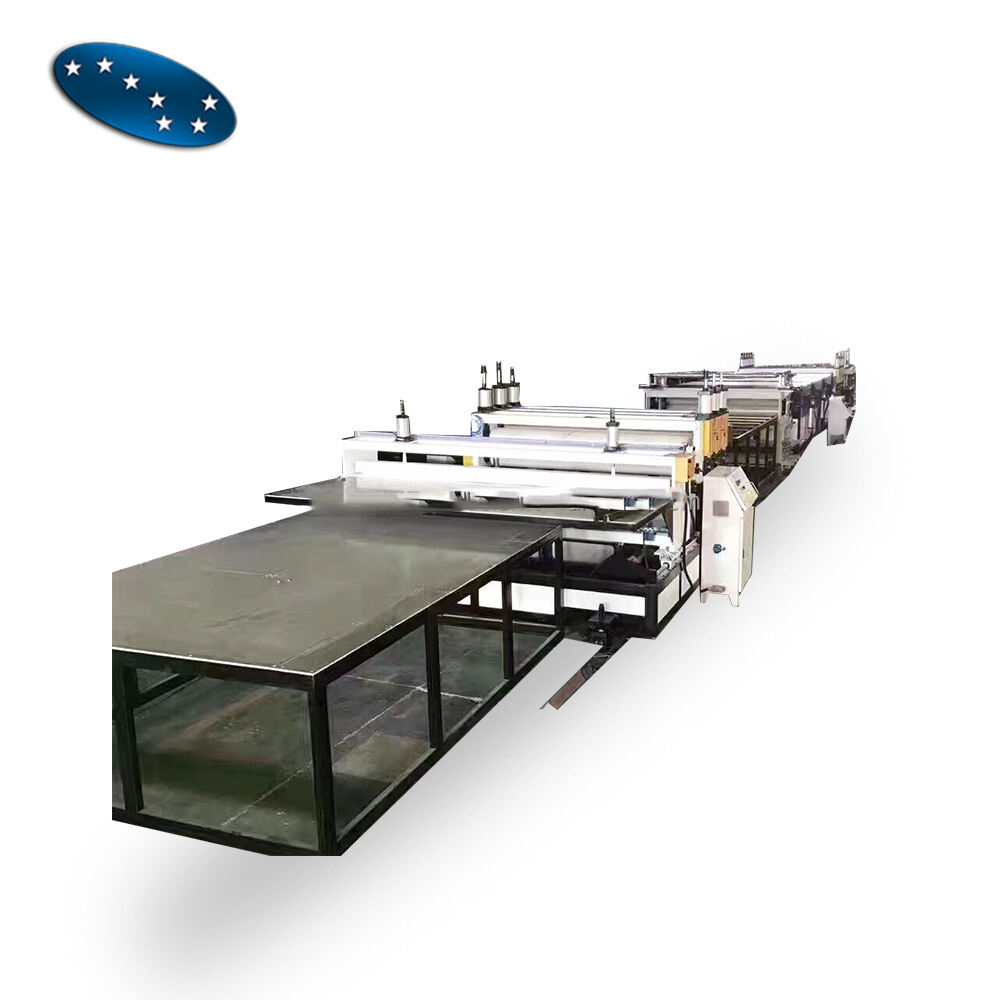

Dopravní platforma

Dopravní platforma