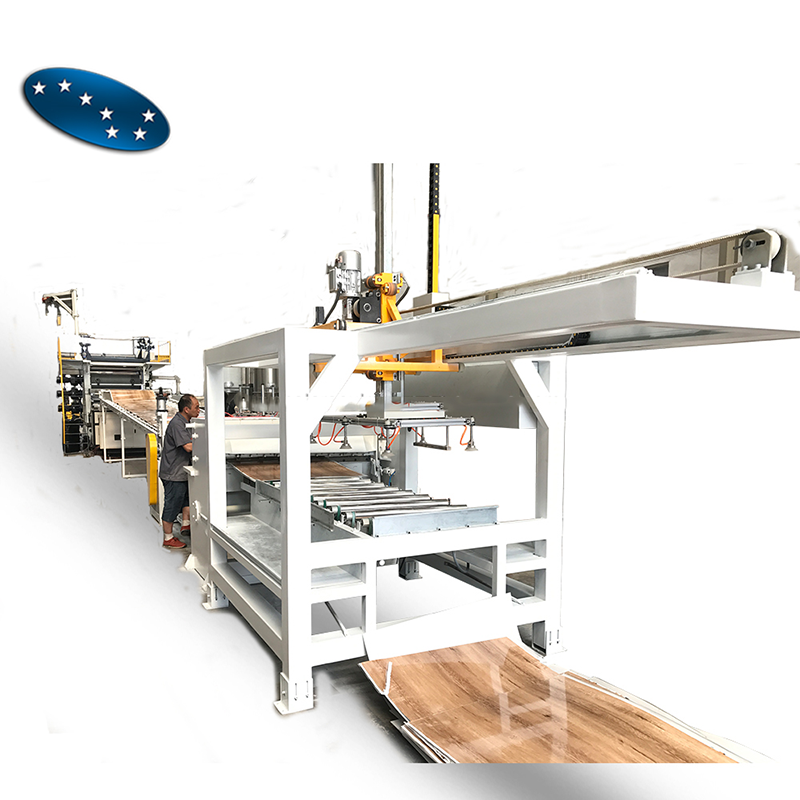

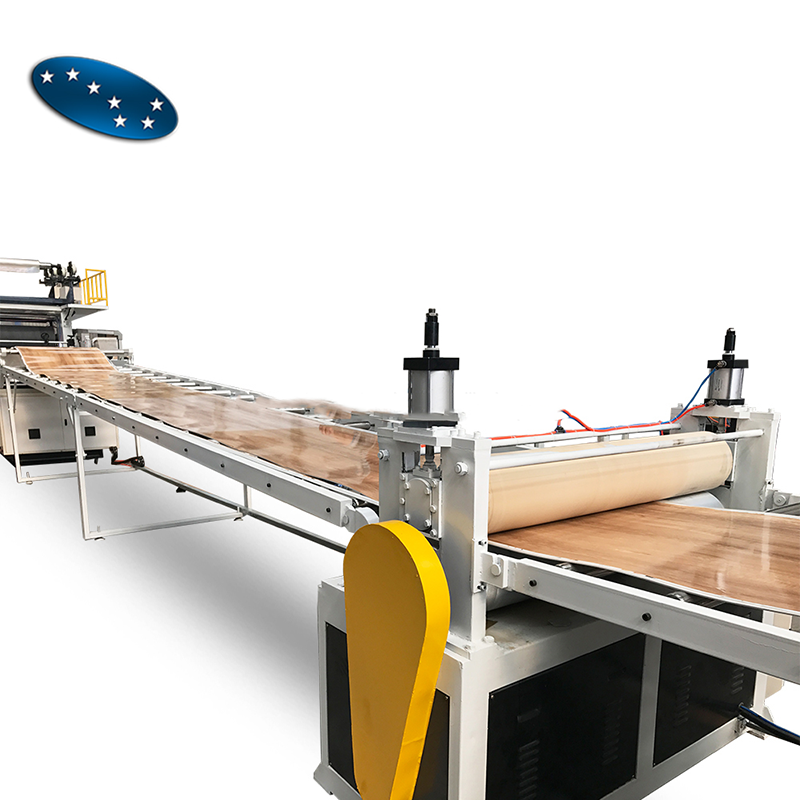

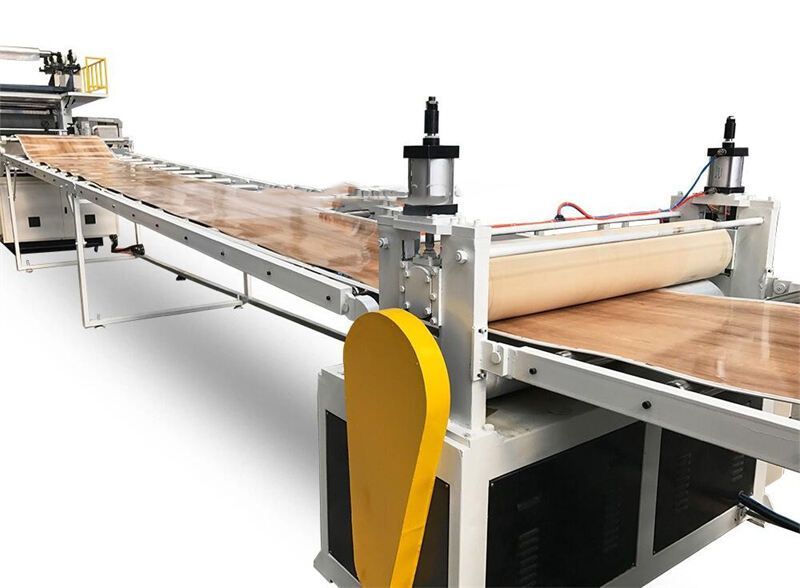

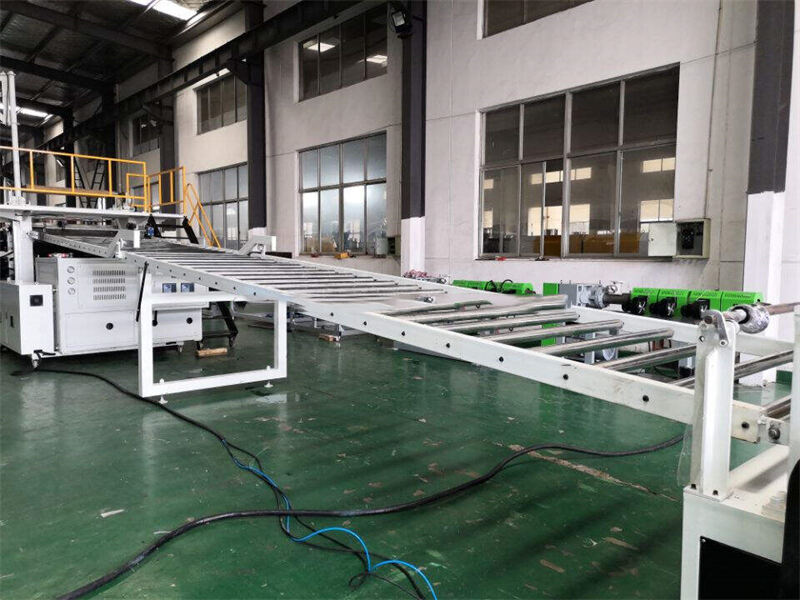

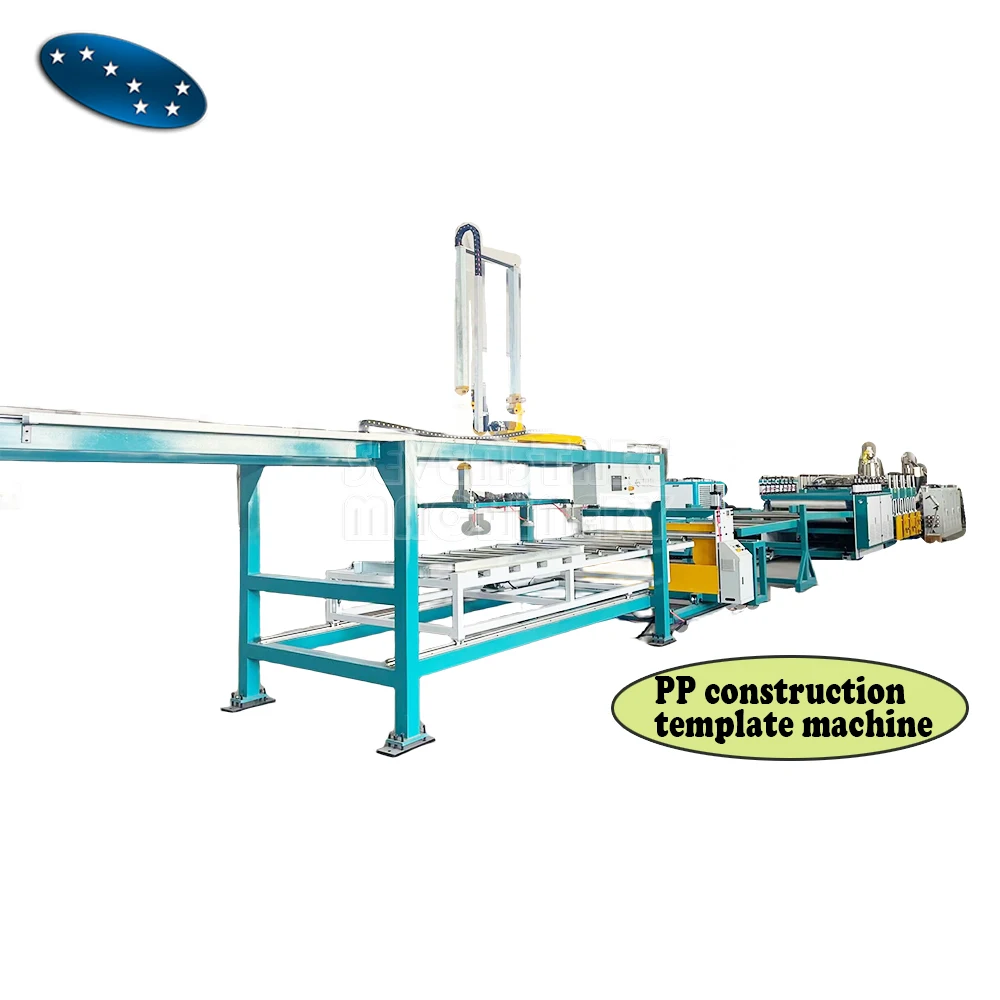

Stone plastic SPC marble sheet board for wall or floor processing machine

Characteristics

(1) Green environmental protection, does not contain formal-dehyde, non-toxic harmless, non radioactive pollution, no pollution to the environment, belong to the green environmental protection products, can be recycled

(2) PVC super wear-resistant floor surface has a layer of special by high-tech processing transparent wear-resistant layer, with wear resistance strong, so PVC floor more and more popular in the hospital, in school, office buildings, shopping malls, supermarkets, transportation and other places

(3) Waterproof, moisture-proof, water is not deformation, non slip PVC material, strong anti slippery, can eliminate the elderly, children's anxiety

(4) Strong elastic shock, comfortable

(5) Safety, insulation, flame retardant, corrosion resistance, acid and alkali resistance, 5% acetic acid. 5% hydrochloric acid, no abnormal surface. Leave the flame for five seconds and can self extinguish

(6) Novel color, a variety of colors available for selection, brilliant color, natural and vivid color, any spell group shape, highlight the individuality color

(7) Installation convenience, convenient construction sawing, planing, nail, glue free paint

(8) Long service life can reach more than 20 years