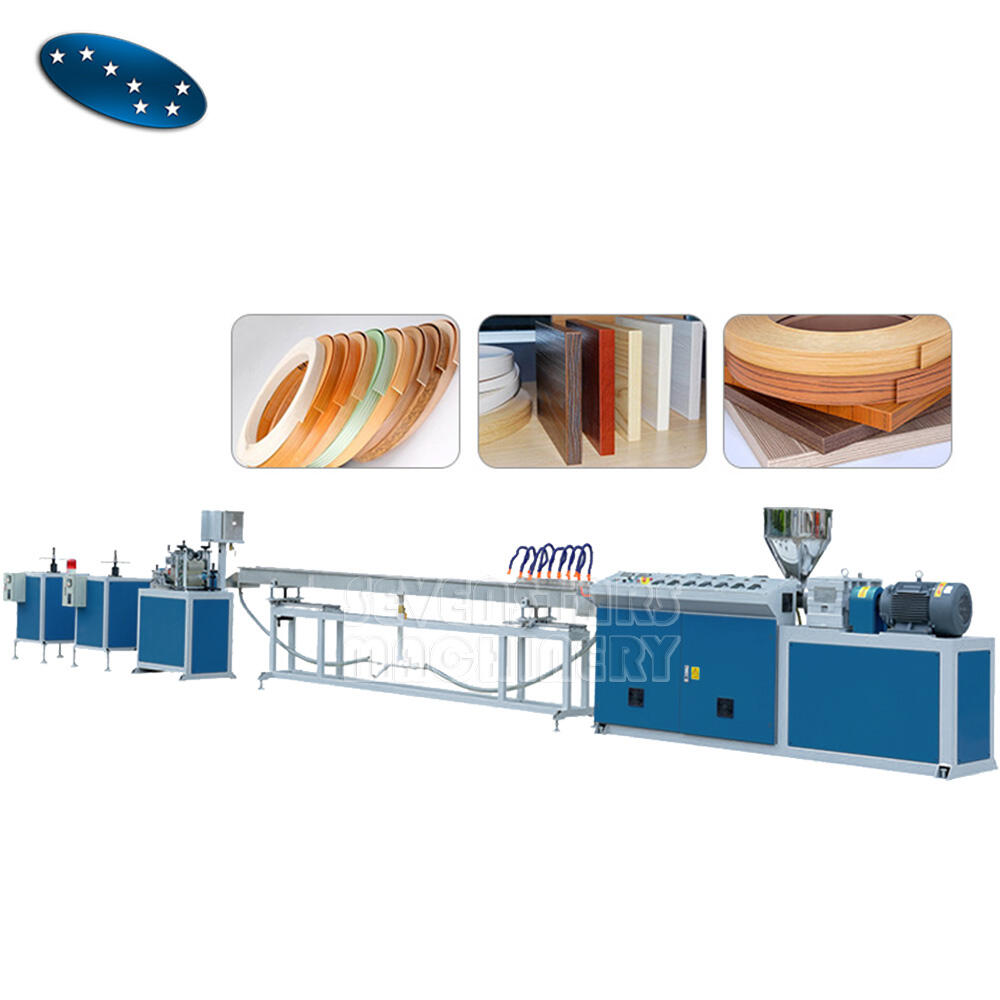

PVC edge banding making machine

PVC edge banding has the following advantages: 1. Low cost: Compared to other materials, PVC edge banding is more affordable and can effectively control production costs. 2. Rich colors: Multiple colors and textures can be provided to match the appearance needs of different boards and meet diverse decorative styles. 3. Good flexibility: It has a certain degree of elasticity and curvature, can adapt to different shapes of board edges, and is relatively easy to install. 4. Strong wear resistance: It can resist friction and wear in daily use to a certain extent, extending the service life of furniture. 5. Excellent waterproof performance: It can effectively prevent moisture from penetrating into the interior of the board, reducing the risk of deformation caused by moisture. 6. High stability: not easily affected by environmental factors such as temperature and humidity, maintaining good physical properties and appearance. 7. Easy to process: It can be easily processed through cutting, trimming, and other methods to meet the needs of different sizes and shapes

Specification

| Model |

SJSZ48(50) |

SJSZ55 |

SJSZ65 |

SJSZ80 |

| Main power(kw) |

15 |

22 |

37 |

55 |

| Product width(mm) |

200-300 |

200-600 |

250-600 |

400-800 |

| Total Power(kw) |

37 |

47 |

66 |

90 |

| Output capacity(kg/h) |

110-160 |

120-190 |

150-210 |

180-400 |

| Length of line |

18.5 |

20 |

21.5 |

24 |

| Air compression(mpa/m3) |

0.5 |

0.6 |

0.6 |

0.6 |

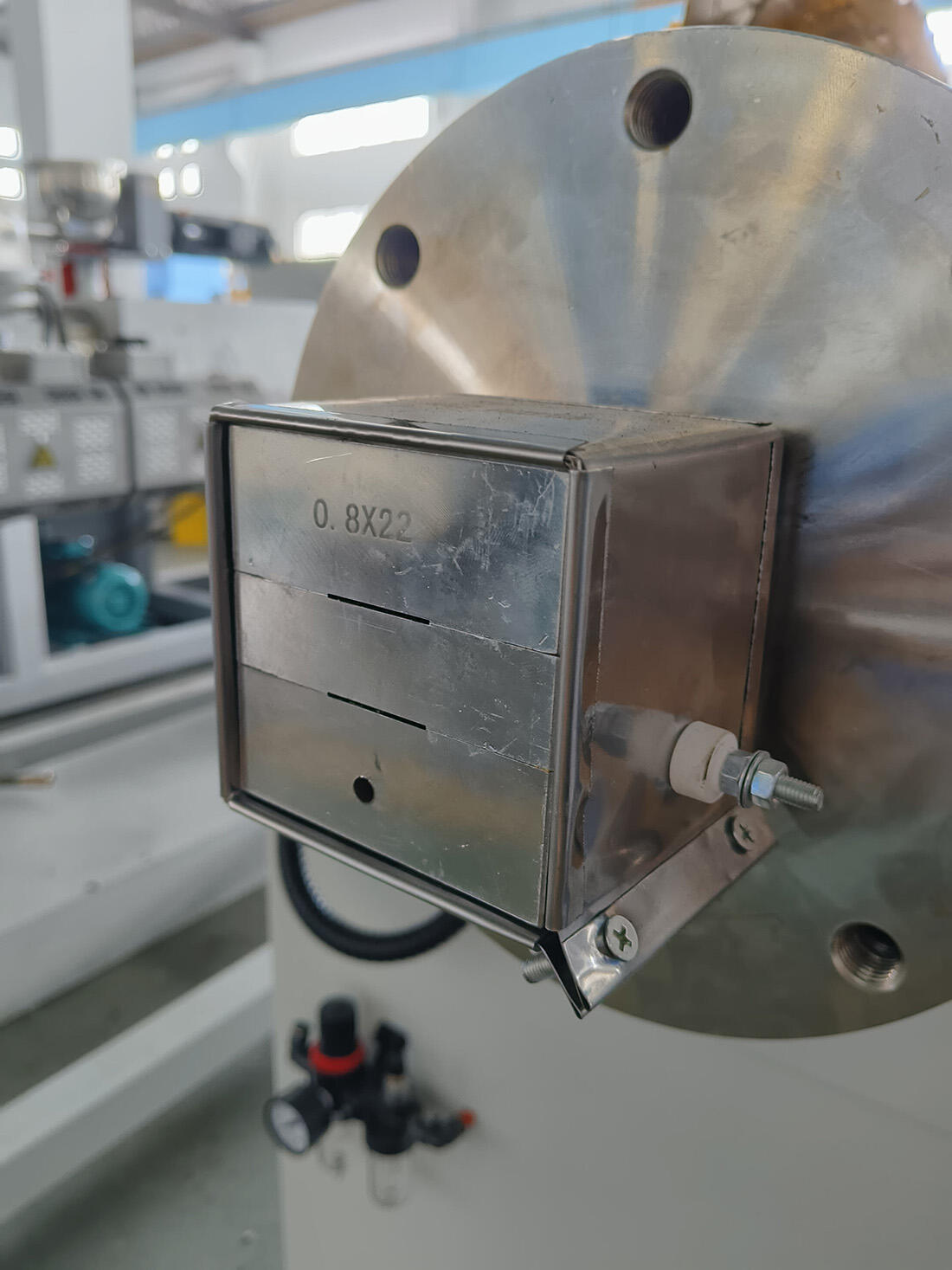

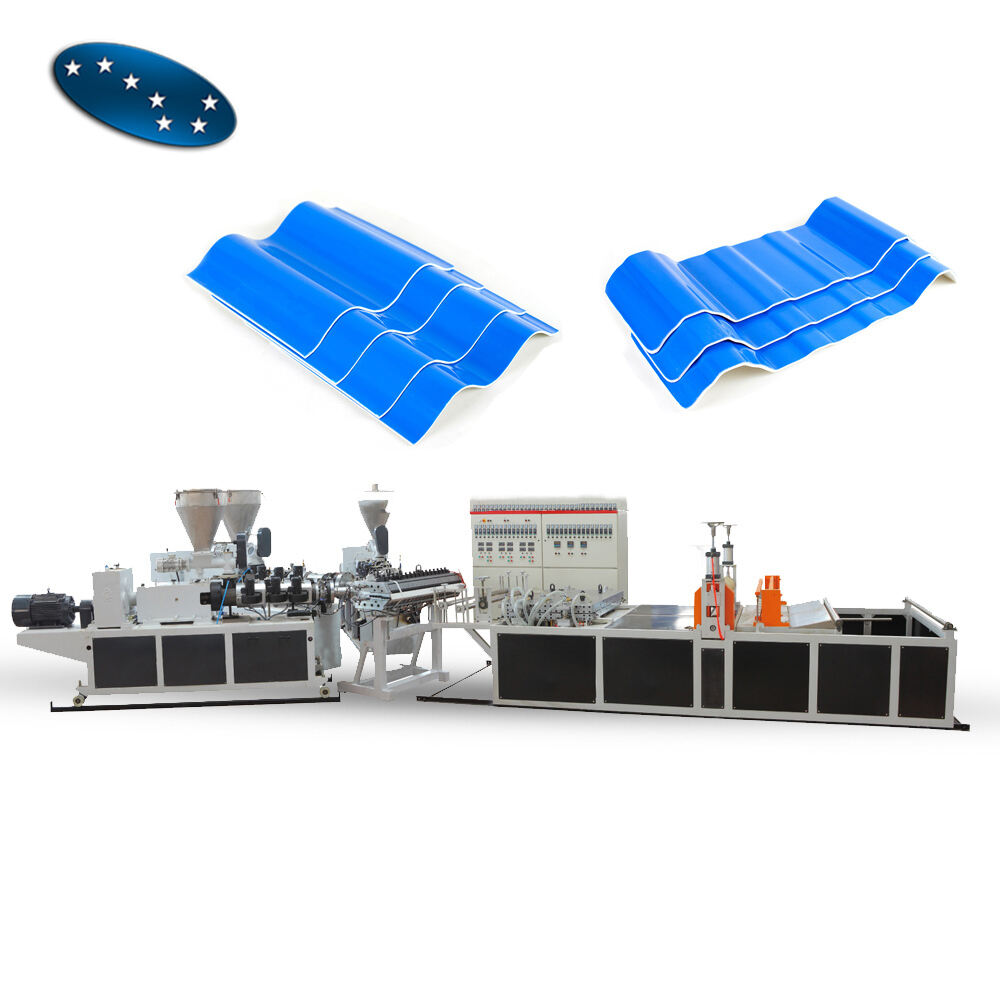

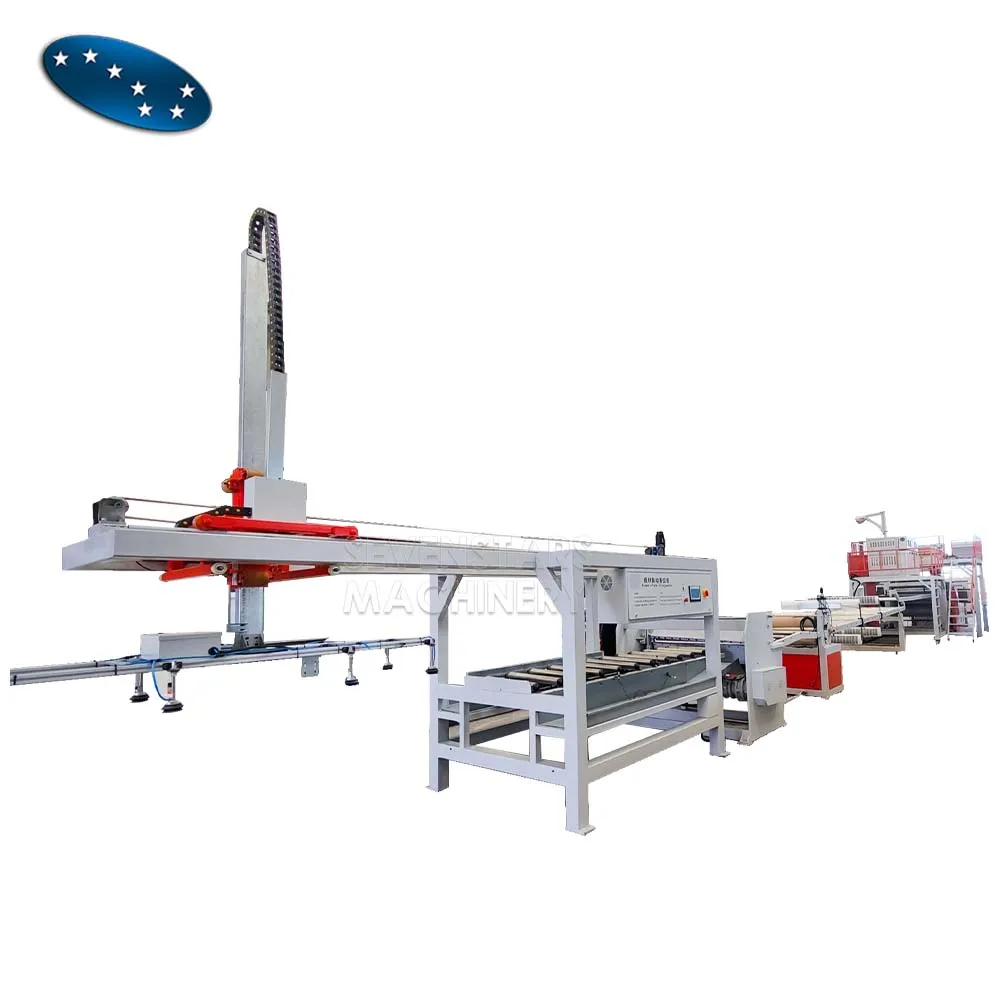

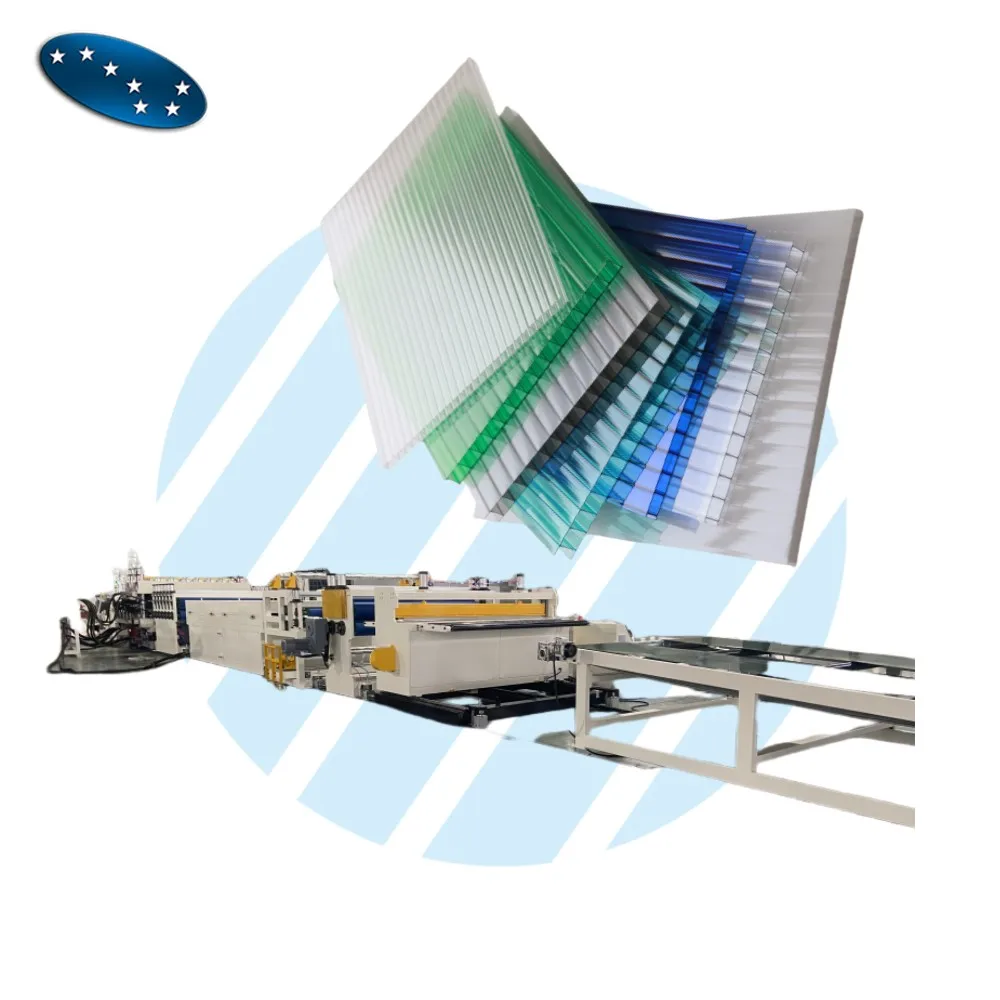

Detailed Images