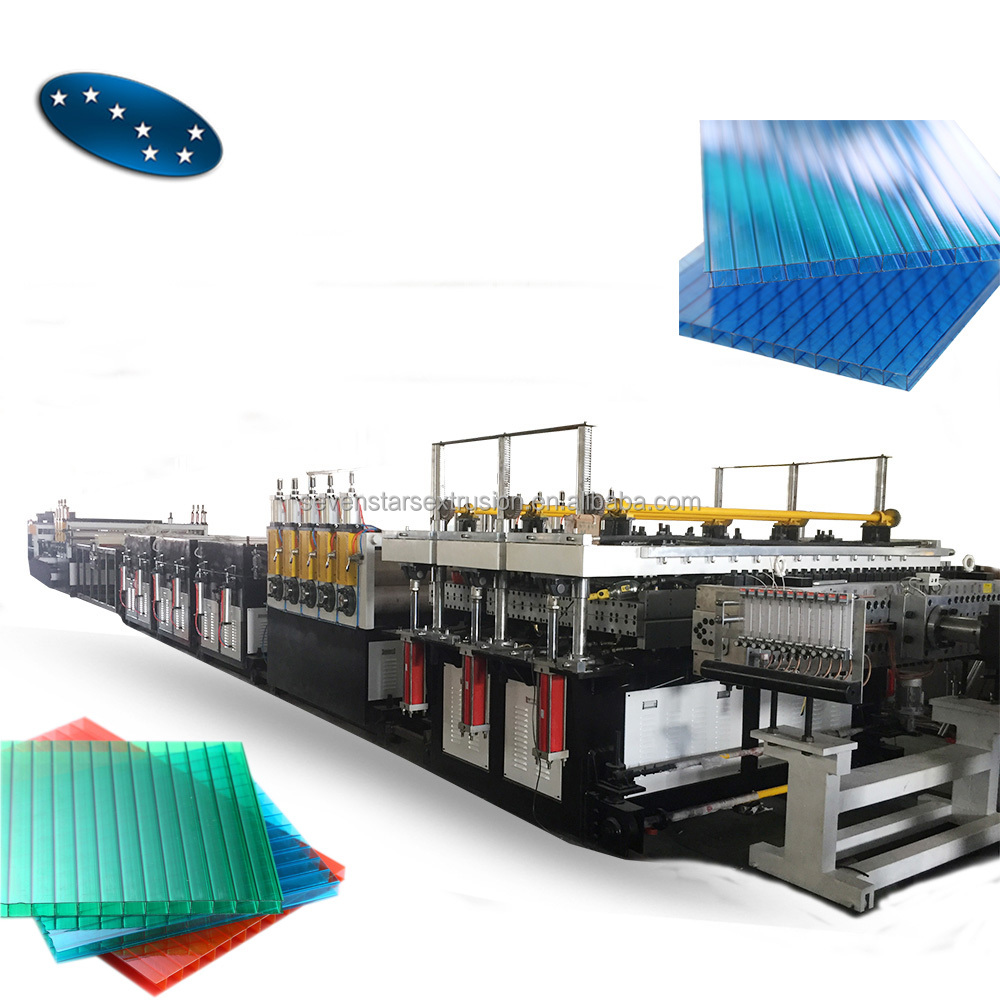

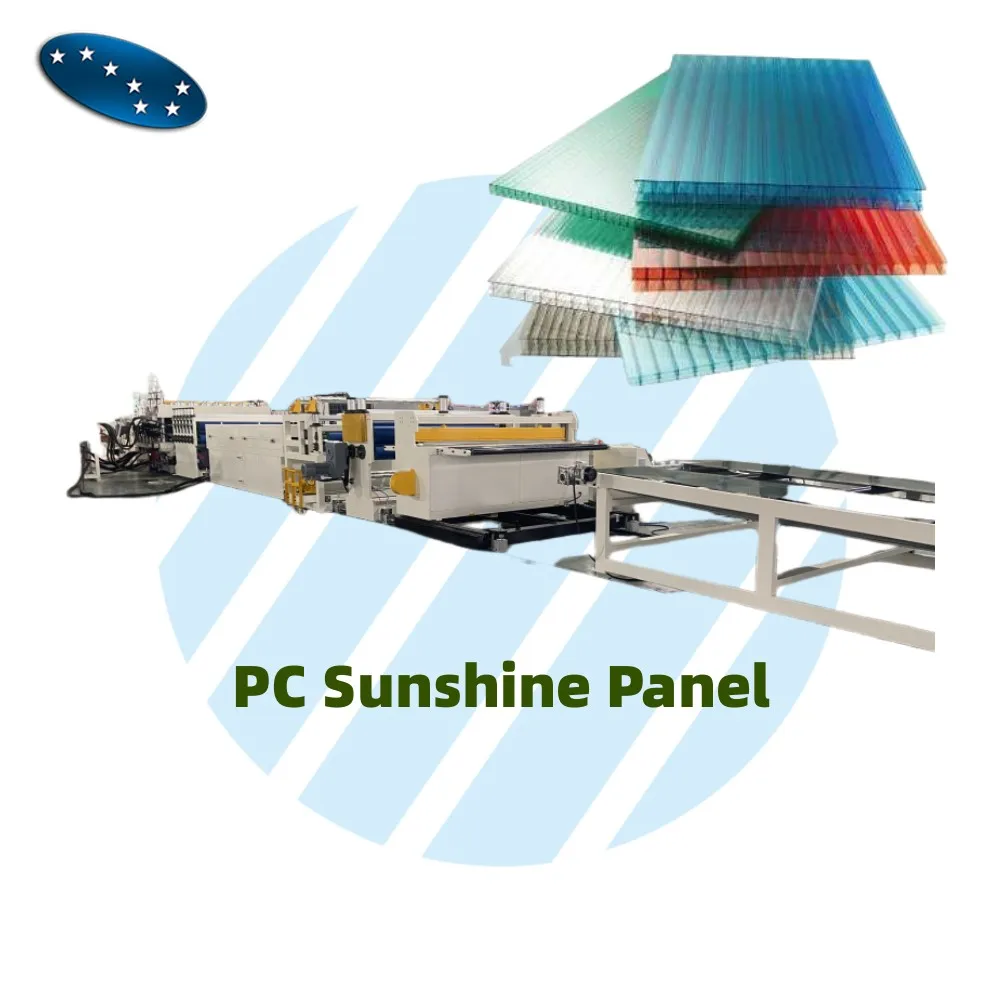

If you're looking for top-quality, durable, and efficient PP pc hollow sheet production line plate sheet making machine, then look no further than the hot-selling offering from SEVENSTARS MACHINERY.

SEVENSTARS MACHINERY is a trusted and reliable brand that has established a reputation for manufacturing and supplying state-of-the-art machinery to a diverse range of industries. With their expertise and experience in the field, they have developed a cutting-edge production line for manufacturing PP pc hollow sheet, which is highly sought-after by manufacturers in the building materials, packaging, and automotive sectors.

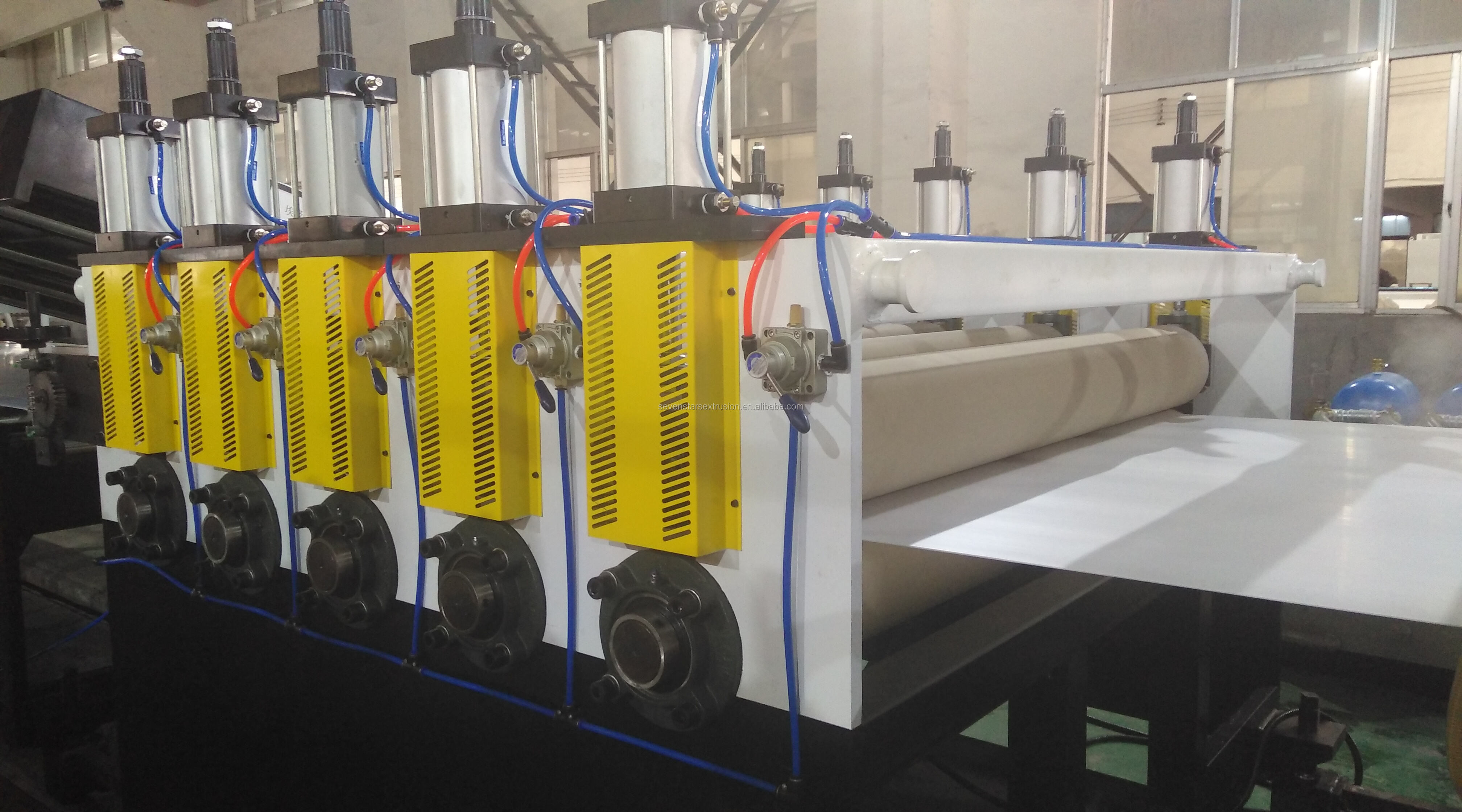

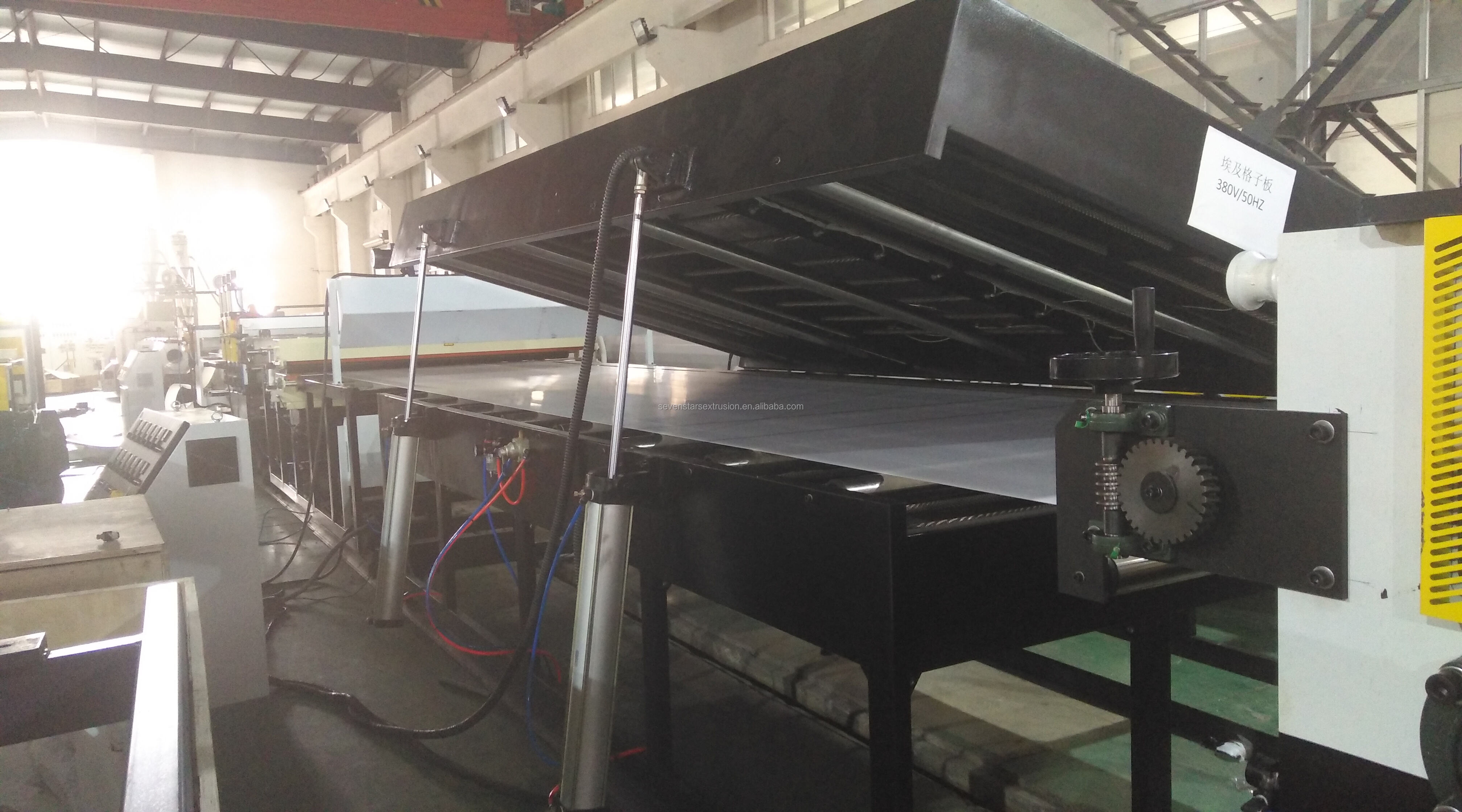

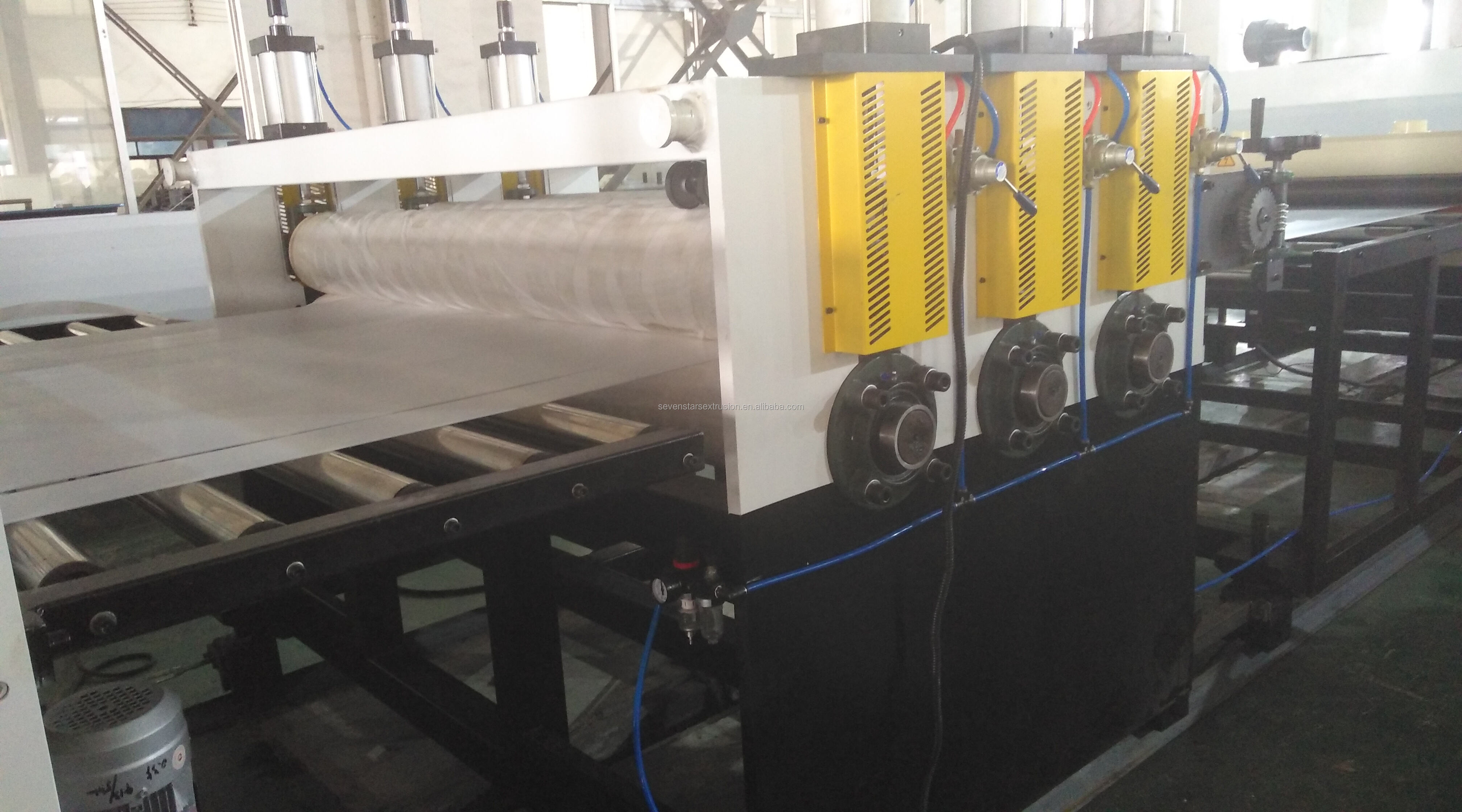

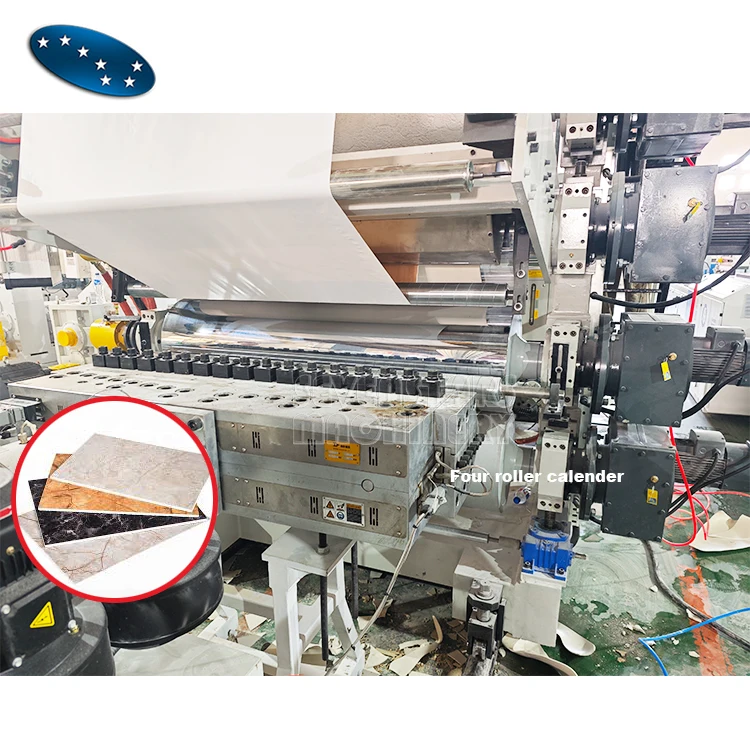

The PP pc hollow sheet production line plate sheet making machine from SEVENSTARS MACHINERY is designed to produce high-quality, light-weight, and durable sheets at a fast production rate. The machine is equipped with advanced technology, including an automatic control system that ensures production is efficient and error-free.

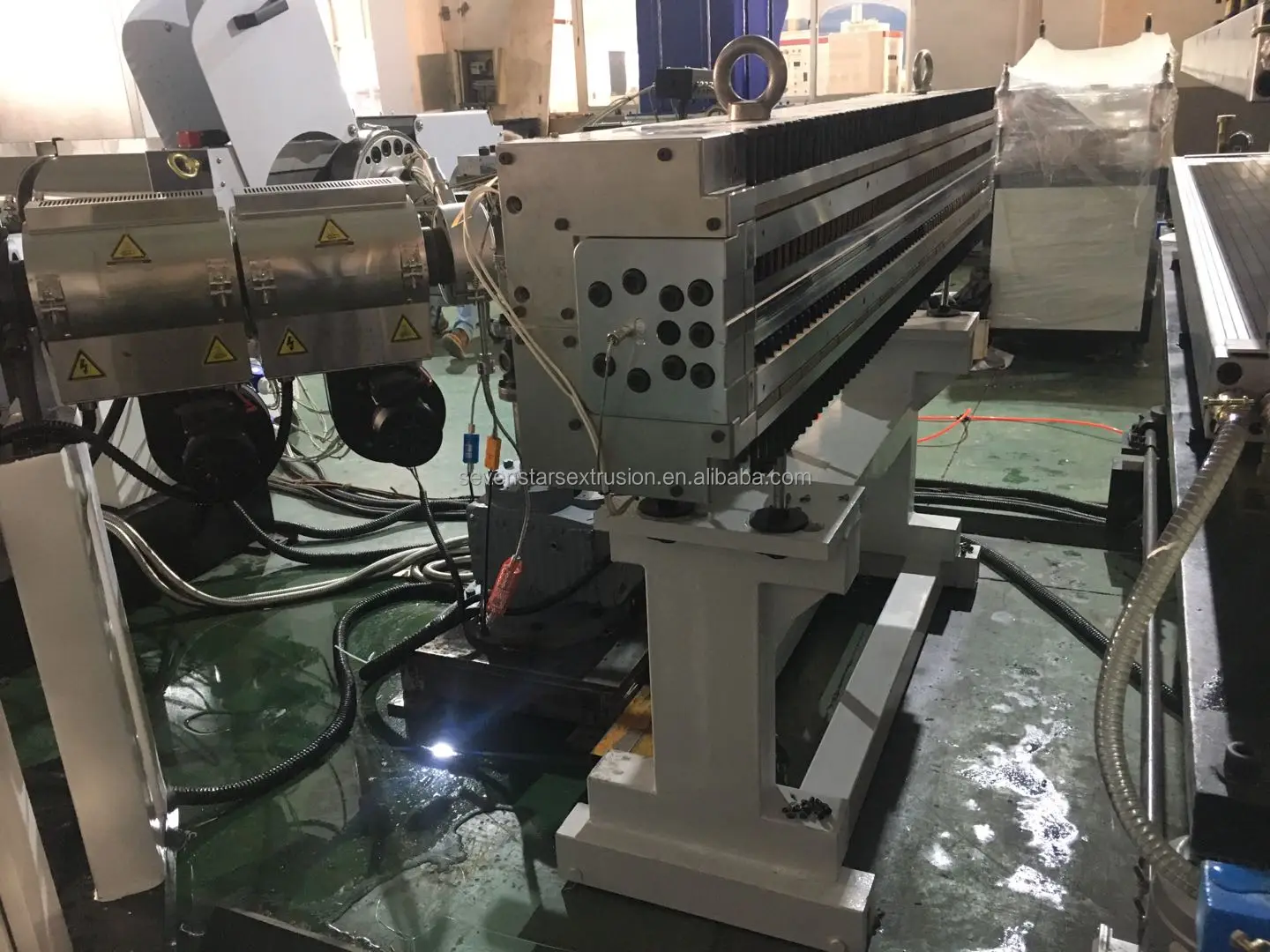

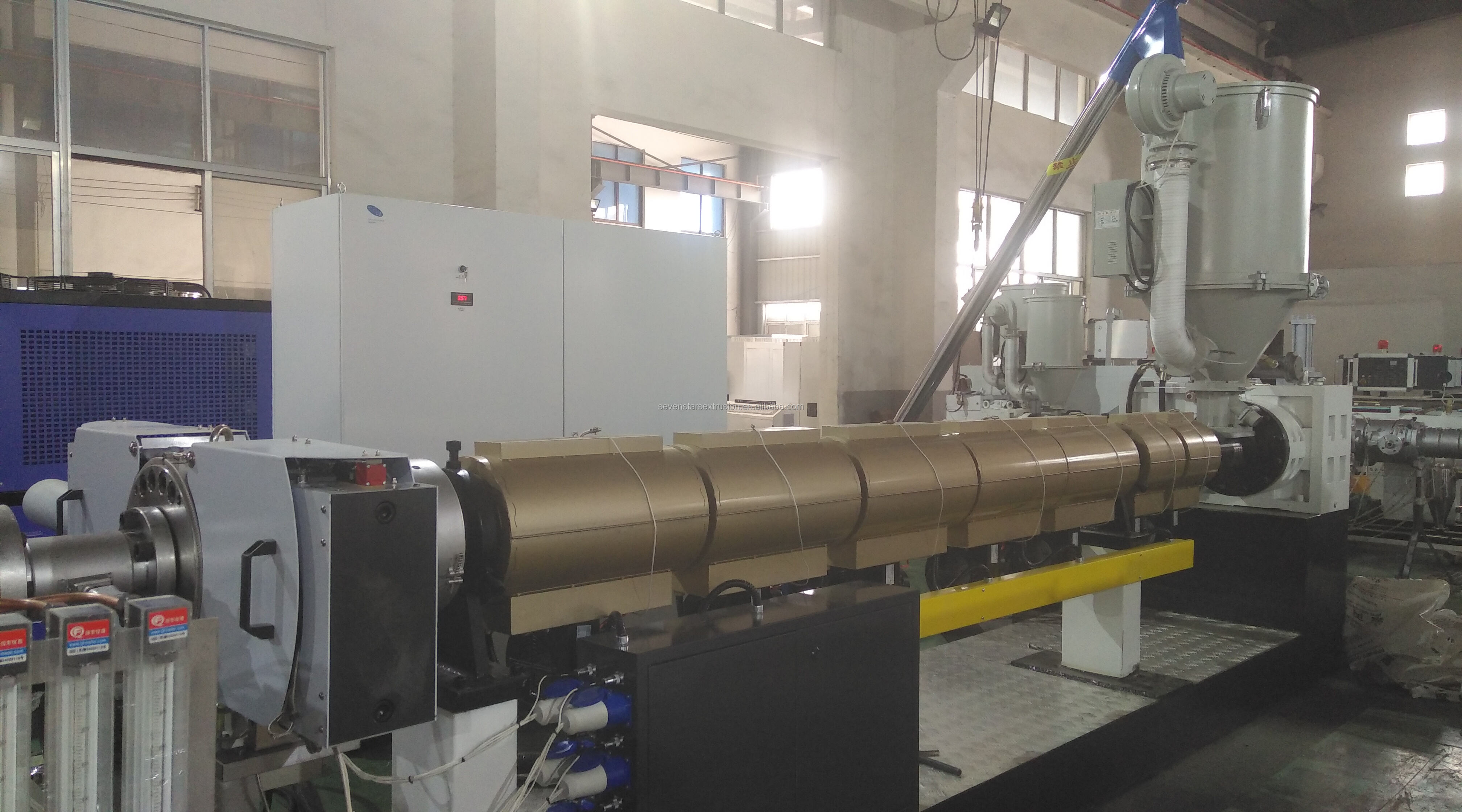

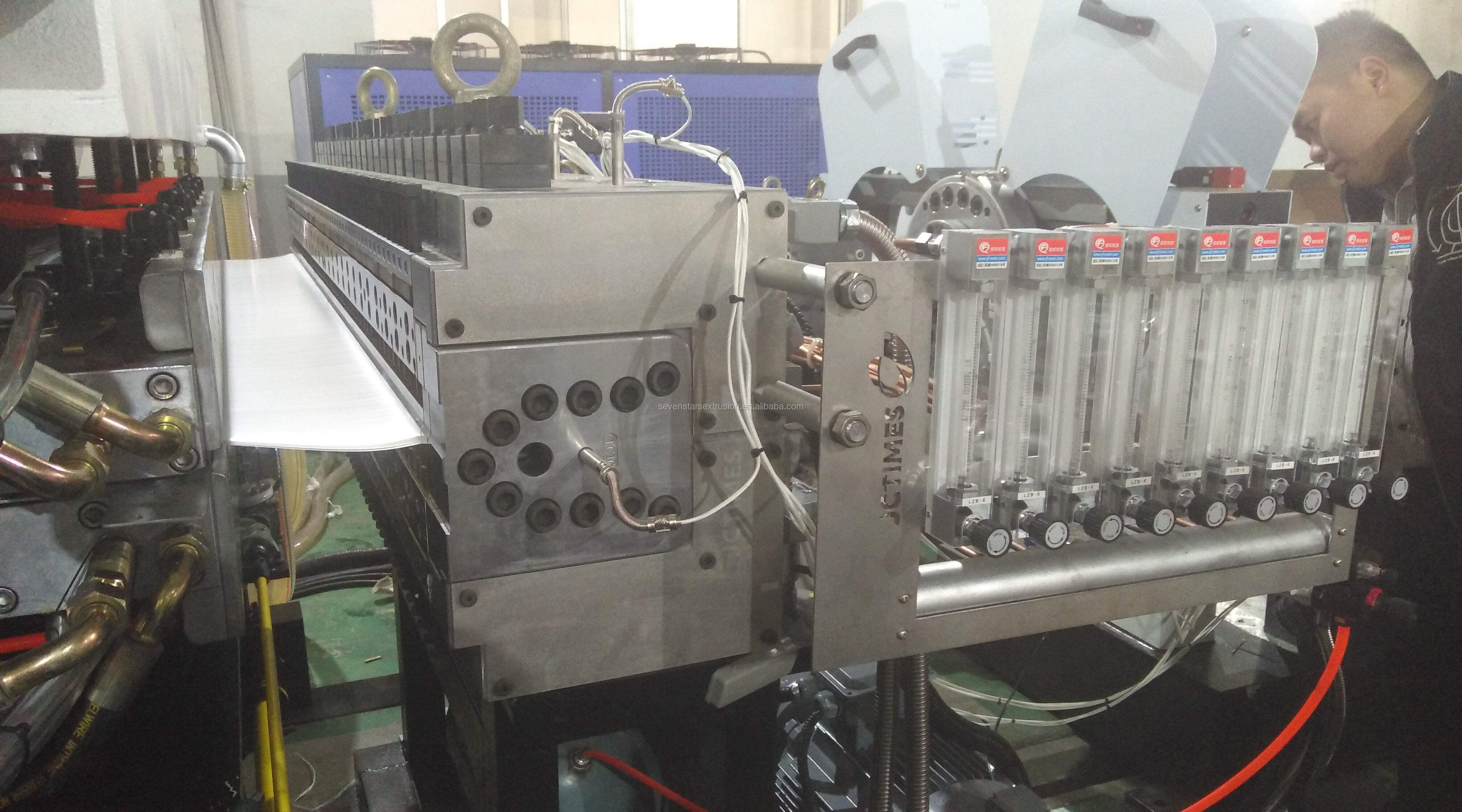

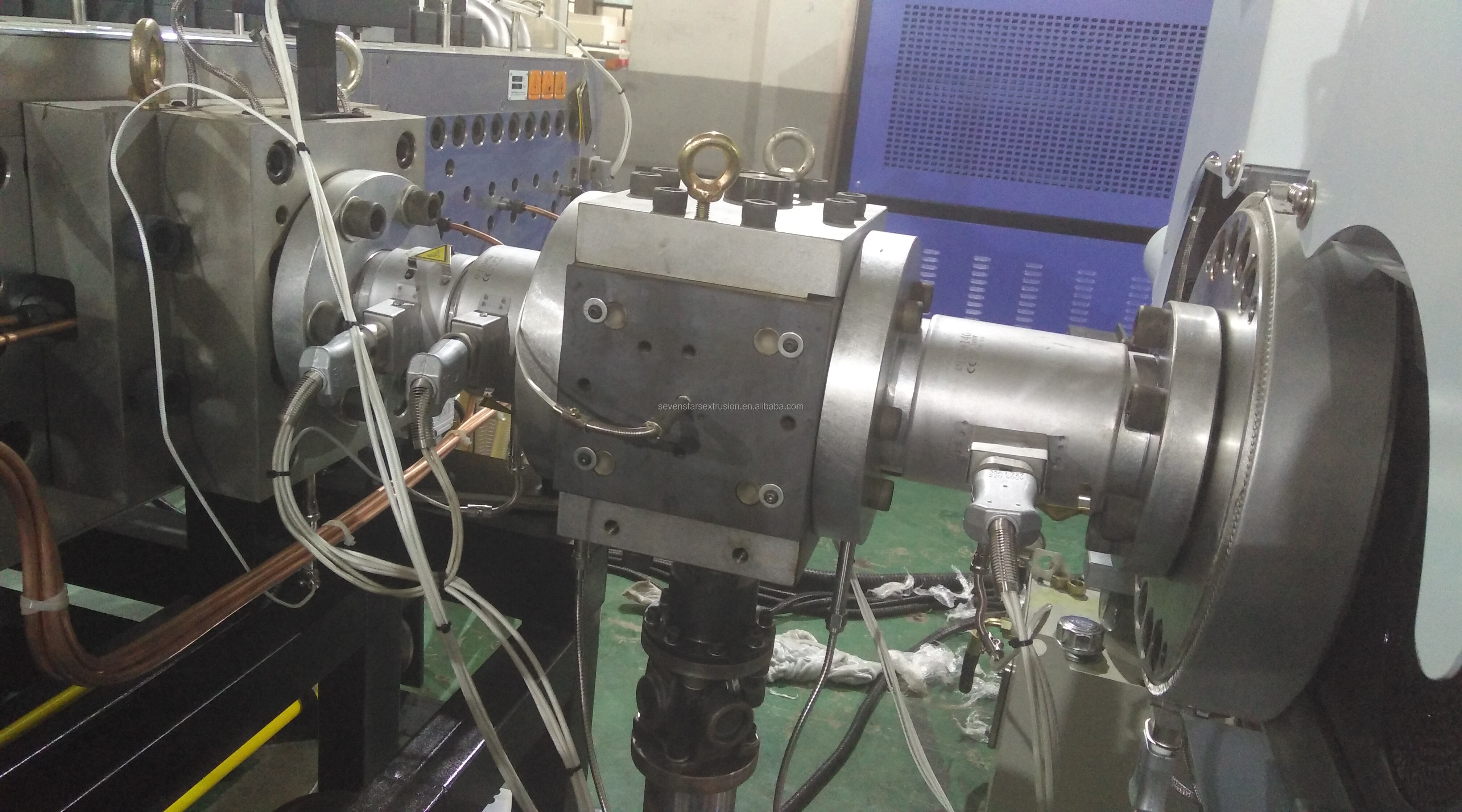

The machine features a robust and reliable extrusion system, which is the heart of the production line. The machine has a high output capacity, producing 200-1000kg per hour depending on the specific model and the thickness of the sheet required.

In addition to the high output capacity, the machine also boasts a user-friendly interface, which makes operation easy and efficient. The touch-screen control panel allows for precise control and monitoring of the process, with features such as temperature control and automatic cut-off for waste material.

The SEVENSTARS MACHINERY’s PP pc hollow sheet production line plate sheet making machine is made from high-quality materials, which ensures that the machine is durable and long-lasting. The machine is also easy to maintain, with simple cleaning and maintenance tasks that can be carried out by operators who have received basic training.

Overall, this production line from SEVENSTARS MACHINERY is an excellent investment for manufacturers in various industries who require durable, lightweight, and cost-effective hollow sheets. The machine is backed by a warranty and after-sales service, ensuring that customers are fully supported throughout the lifespan of the machine.

If you are looking for a high-quality, reliable, and efficient PP pc hollow sheet production line plate sheet making machine, then SEVENSTARS MACHINERY is the brand to choose. Their machine is designed to meet the needs of manufacturers in various industries, and their excellent reputation in the market is a testament to their commitment to excellence, quality, and reliability

PP pc hollow sheet production line plate sheet making machine hot sale

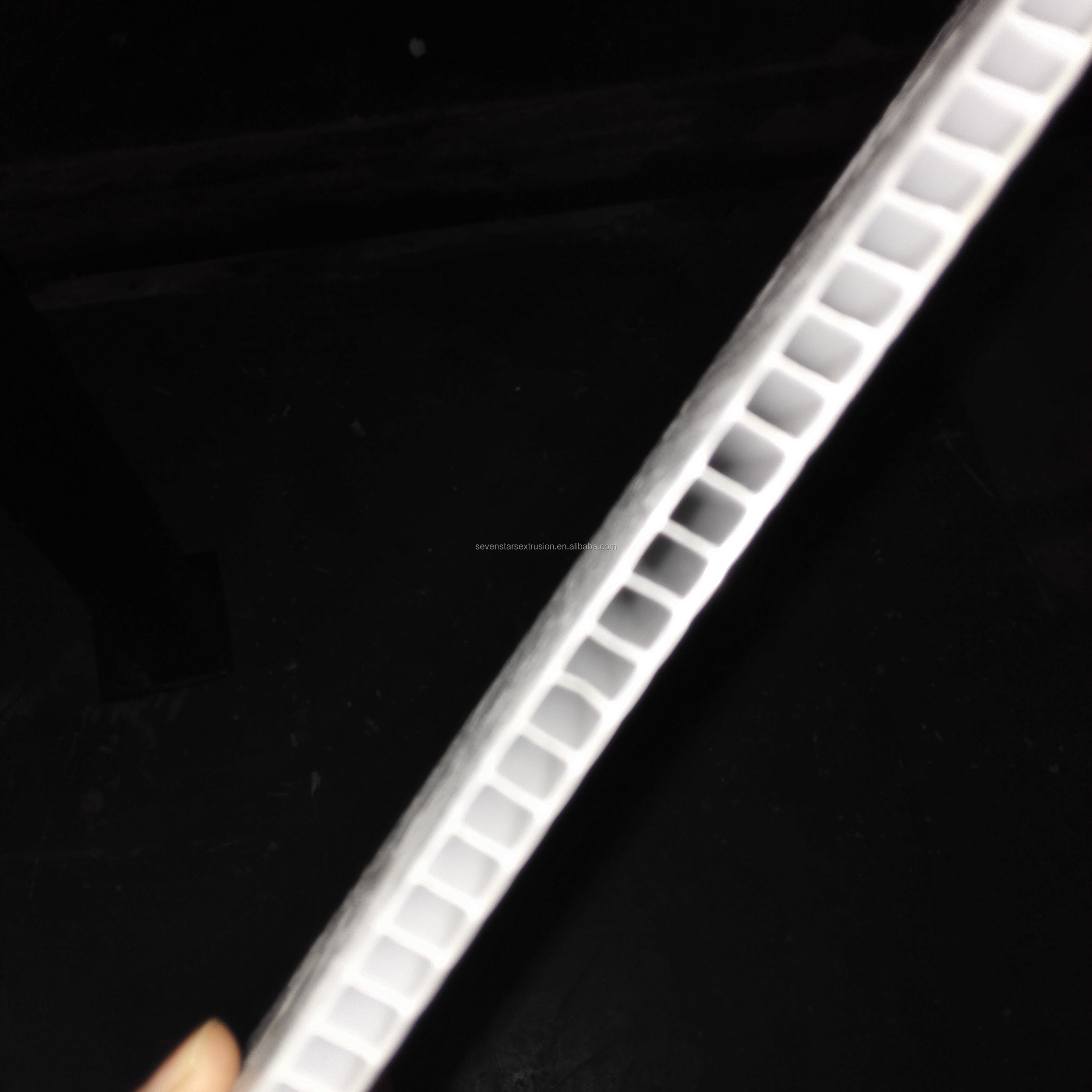

The company's research and development of the leading product is "complete sets of hollow lattice production line and mold", according to the thickness of the product, width, structure, shape, the use of different plastic raw materials have different categories:

1. According to product width: can be divided into 1400mm, 1800mm, 2100mm, 2300mm unit

2. According to product thickness: can be divided into 2-6mm, 6-12mm, 12-18mm unit

3. According to the product structure: Can be divided into double wall, three wall, four wall,

4. According to product shape: can be divided into ordinary I type, S type, V type, X type, meter type

5. According to the use of plastic raw materials products: can be divided into PP, PE, PC

PP hollow sheet application

The PP hollow grid board can be processed into turnover case, packaging case, clapboard, lining board, backing board and pallet, etc, due to its advantages of light weight, high tenacity, damp proof, environmental performance and secondary processing. It is widely used in such fields as the electron, household electrical appliances, packaging, machinery, postal, food, medicine, pesticide and advertisement decoration, etc

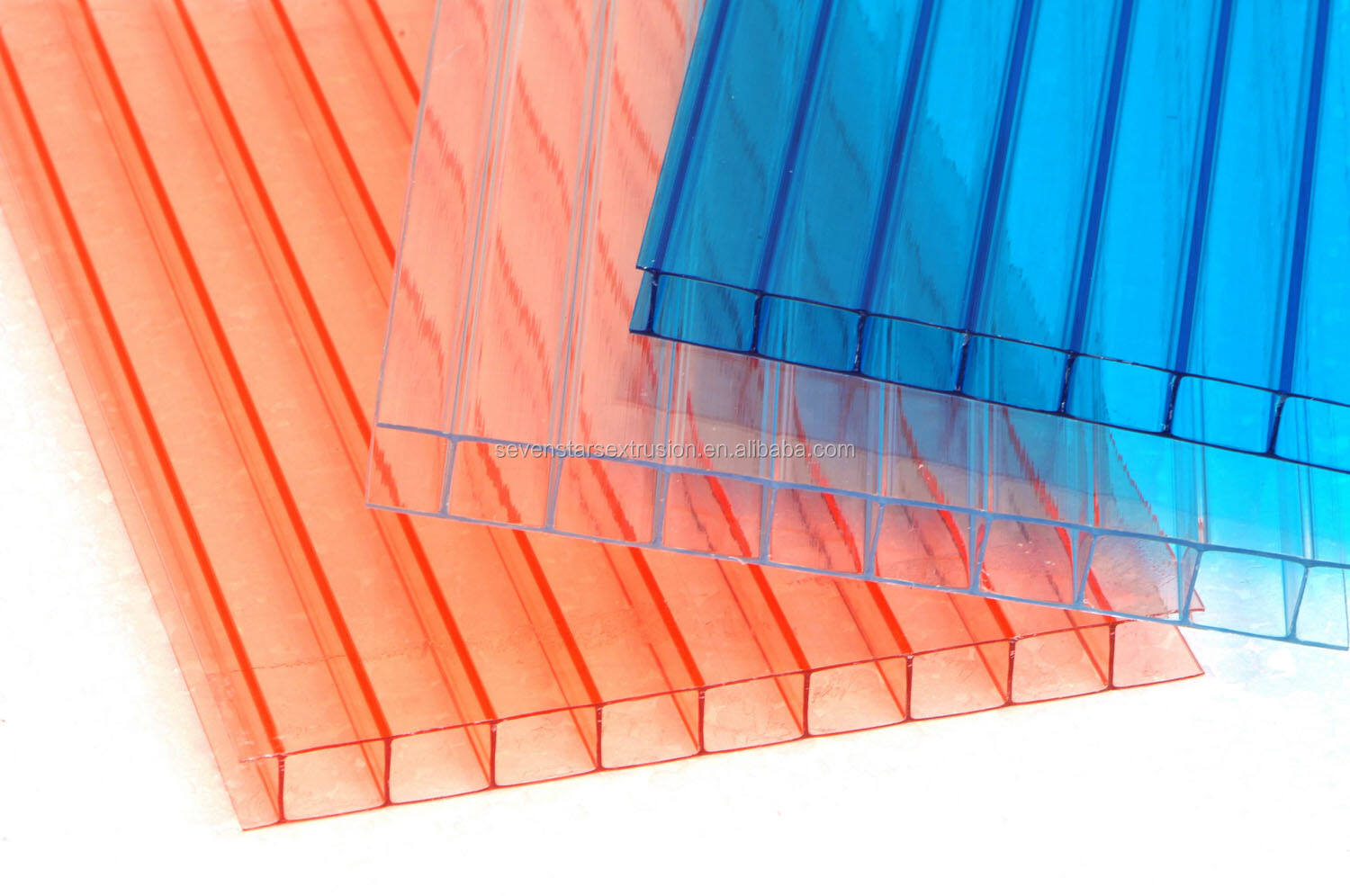

PC hollow sheet application

PC Hollow sheet is widely used as sun proof ceilings of office building, hall, market, stadium, recreation center and public facilities; weather shed of bus station, summer house, and corridor of lounge hall; Safe sun-proof ceilings of airport and factories, Velarium of modernized agriculture, livestock breeding industry and indoor swimming pools; noise

barrier on high way and elevated road in cities, advertisement billboard, lighting box and exhibition decoration; partition wall between office and living room, and between bathroom and toilet

Model of PP pc hollow sheet production line plate sheet making machine hot sale

Extruder model |

Φ100 |

Φ120 |

Product width |

1300/1500mm |

2100mm |

Product thickness |

2-12mm |

2-12mm |

Motor power |

110kw |

132kw |

Capacity |

250-300kg/h |

400-450kg/h |

Seaworthy packing with bubble film and strengthen film

Zhangjiagang Sevenstars Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders, high speed mixers and various plastic auxiliary machines

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time

Why choose us

1. Low cost* All the machine, we make it ourself to reduce the cost of our customer

2. Genuine product with excellent quality* We choose our material very strict

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier

3. Engerneers available to serve oversea4. Quick delivery* The company provide just in time delivery with its streamlined supply chain

5. Cost saving* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out, then delivered to our customer.

* All about that pushing up the price, but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

EN

EN