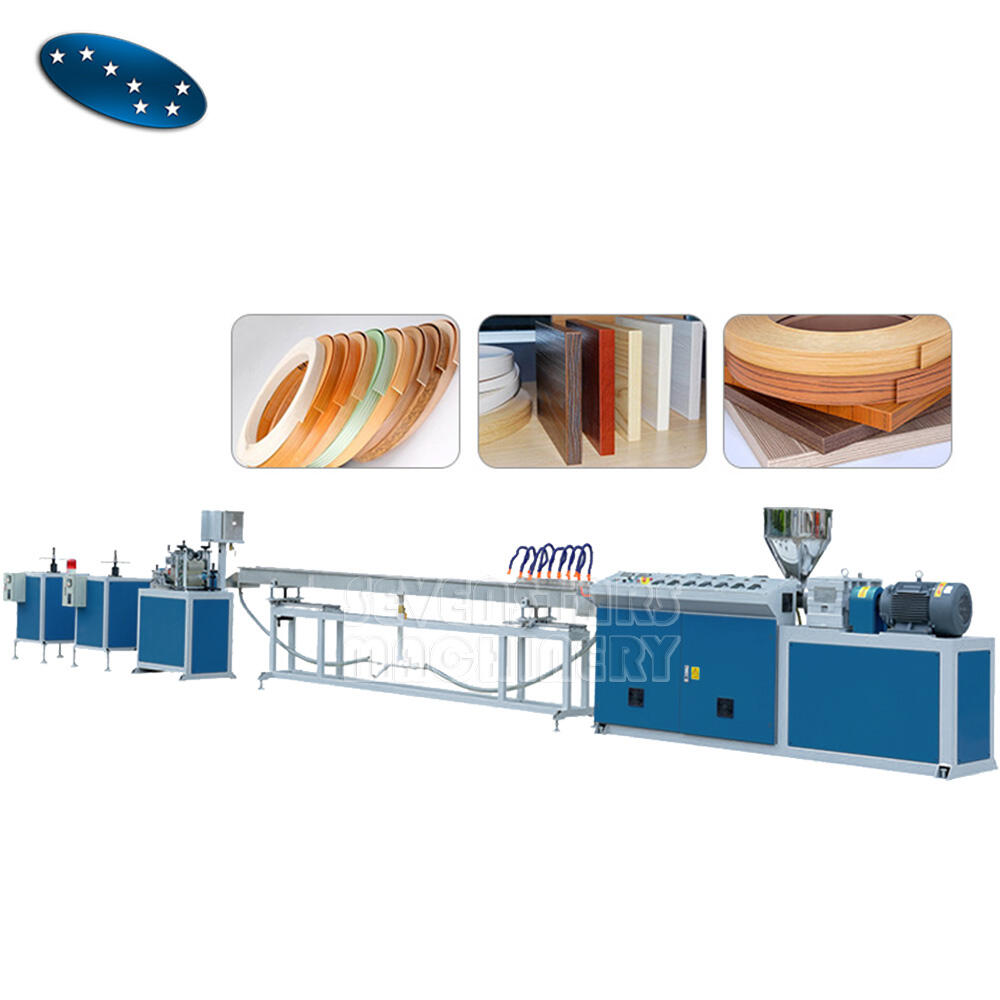

PVC edge banding extrusion machine

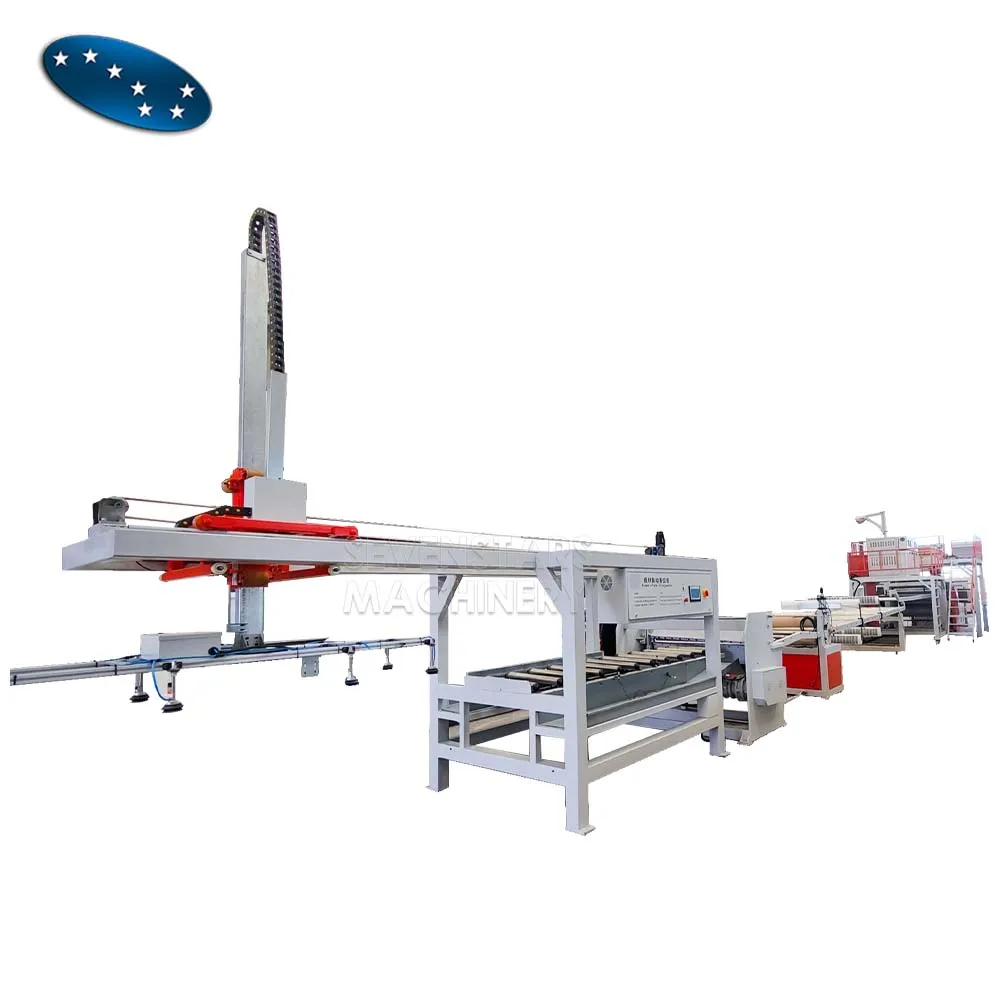

This printing line is suitable for printing various wood grain and other exquisite patterns on the surface of PVC edge banding, wood veneer edge banding, and PVC frame banding. This line can complete the printing, surface coating, and UV drying process in one go.

The machine boasts an impressive extrusion capacity of up to 350kg/h, making it one of the fastest and most efficient machines on the market today. It also comes with high-quality temperature controllers that ensure the perfect temperature for the material. This is crucial for producing edge banding that is strong, resilient, and resistant to common wear and tear.

To make the production process smoother, the machine is equipped with an easy-to-use HMI touch screen interface. This interface allows the operator to adjust the production settings more accurately, ensuring consistent quality on every single output. The machine also features a fully automatic control system, making it user-friendly and efficient.

Equipment list

1. Single-screw extruder2. 2 cavity mold for edge banding

3. Cooling tank and embossing device

4. Traction glue machine

5. winding machine

6. PVC Pelletizing line

7. Edge banding printing line

Specification

| Model |

SJSZ48(50) |

SJSZ55 |

SJSZ65 |

SJSZ80 |

| Main power(kw) |

15 |

22 |

37 |

55 |

| Product width(mm) |

200-300 |

200-600 |

250-600 |

400-800 |

| Total Power(kw) |

37 |

47 |

66 |

90 |

| Output capacity(kg/h) |

110-160 |

120-190 |

150-210 |

180-400 |

| Length of line |

18.5 |

20 |

21.5 |

24 |

| Air compression(mpa/m3) |

0.5 |

0.6 |

0.6 |

0.6 |

Detailed Images

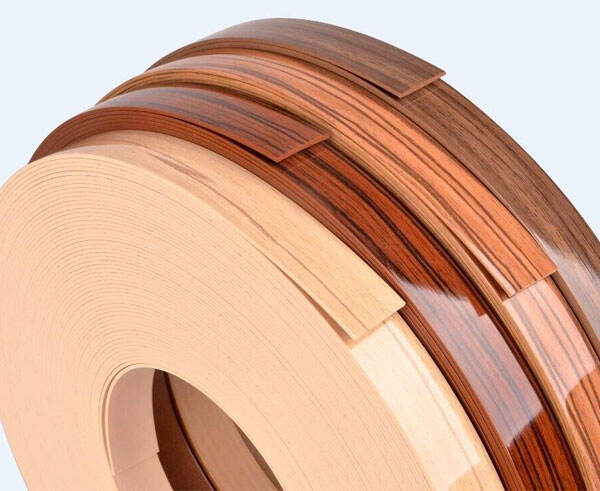

Products made by extruding PVC edge banding with a single screw extruder have better quality compared to conical twin-screw extruders